Page 100 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 100

PIPING

2.50 CHAPTER TWO

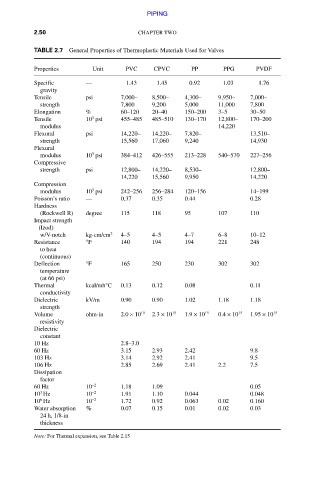

TABLE 2.7 General Properties of Thermoplastic Materials Used for Valves

Properties Unit PVC CPVC PP PPG PVDF

Specific — 1.43 1.45 0.92 1.03 1.76

gravity

Tensile psi 7,000– 8,500– 4,300– 9,950– 7,000–

strength 7,800 9,200 5,000 11,000 7,800

Elongation % 60–120 20–40 150–200 3–5 30–50

Tensile 10 3 psi 455–485 485–510 130–170 12,800– 170–200

modulus 14,220

Flexural psi 14,220– 14,220– 7,820– 13,510–

strength 15,560 17,060 9,240 14,930

Flexural

3

modulus 10 psi 384–412 426–555 213–228 540–570 227–256

Compressive

strength psi 12,800– 14,220– 8,530– 12,800–

14,220 15,560 9,950 14,220

Compression

3

modulus 10 psi 242–256 256–284 120–156 14–199

Poisson’s ratio — 0.37 0.35 0.44 0.28

Hardness

(Rockwell R) degree 115 118 95 107 110

Impact strength

(Izod)

w/V-notch kg-cm/cm 2 4–5 4–5 4–7 6–8 10–12

Resistance °F 140 194 194 221 248

to heat

(continuous)

Deflection °F 165 250 230 302 302

temperature

(at 66 psi)

Thermal kcal/mh°C 0.13 0.12 0.08 0.11

conductivity

Dielectric kV/m 0.90 0.90 1.02 1.18 1.18

strength

Volume ohm-in 2.0 × 10 15 2.3 × 10 15 1.9 × 10 15 0.4 × 10 15 1.95 × 10 15

resistivity

Dielectric

constant

10 Hz 2.8–3.0

60 Hz 3.15 2.93 2.42 9.8

103 Hz 3.14 2.92 2.41 9.5

106 Hz 2.85 2.69 2.41 2.2 7.5

Dissipation

factor

60 Hz 10 −2 1.18 1.09 0.05

3

10 Hz 10 −2 1.91 1.10 0.044 0.048

6

10 Hz 10 −2 1.72 0.92 0.063 0.02 0.160

Water absorption % 0.07 0.15 0.01 0.02 0.03

24 h, 1/8-in

thickness

Note: For Thermal expansion, see Table 2.15

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.