Page 96 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 96

PIPING

2.46 CHAPTER TWO

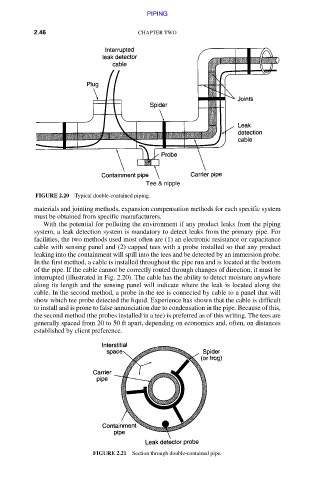

FIGURE 2.20 Typical double-contained piping.

materials and jointing methods, expansion compensation methods for each specific system

must be obtained from specific manufacturers.

With the potential for polluting the environment if any product leaks from the piping

system, a leak detection system is mandatory to detect leaks from the primary pipe. For

facilities, the two methods used most often are (1) an electronic resistance or capacitance

cable with sensing panel and (2) capped tees with a probe installed so that any product

leaking into the containment will spill into the tees and be detected by an immersion probe.

In the first method, a cable is installed throughout the pipe run and is located at the bottom

of the pipe. If the cable cannot be correctly routed through changes of direction, it must be

interrupted (illustrated in Fig. 2.20). The cable has the ability to detect moisture anywhere

along its length and the sensing panel will indicate where the leak is located along the

cable. In the second method, a probe in the tee is connected by cable to a panel that will

show which tee probe detected the liquid. Experience has shown that the cable is difficult

to install and is prone to false annunciation due to condensation in the pipe. Because of this,

the second method (the probes installed in a tee) is preferred as of this writing. The tees are

generally spaced from 20 to 50 ft apart, depending on economics and, often, on distances

established by client preference.

FIGURE 2.21 Section through double-contained pipe.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.