Page 93 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 93

PIPING

PIPING 2.43

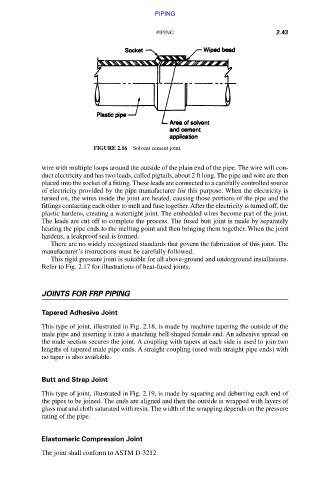

FIGURE 2.16 Solvent cement joint.

wire with multiple loops around the outside of the plain end of the pipe. The wire will con-

duct electricity and has two leads, called pigtails, about 2 ft long. The pipe and wire are then

placed into the socket of a fitting. These leads are connected to a carefully controlled source

of electricity provided by the pipe manufacturer for this purpose. When the electricity is

turned on, the wires inside the joint are heated, causing those portions of the pipe and the

fittings contacting each other to melt and fuse together. After the electricity is turned off, the

plastic hardens, creating a watertight joint. The embedded wires become part of the joint.

The leads are cut off to complete the process. The fused butt joint is made by separately

heating the pipe ends to the melting point and then bringing them together. When the joint

hardens, a leakproof seal is formed.

There are no widely recognized standards that govern the fabrication of this joint. The

manufacturer’s instructions must be carefully followed.

This rigid pressure joint is suitable for all above-ground and underground installations.

Refer to Fig. 2.17 for illustrations of heat-fused joints.

JOINTS FOR FRP PIPING

Tapered Adhesive Joint

This type of joint, illustrated in Fig. 2.18, is made by machine tapering the outside of the

male pipe and inserting it into a matching bell-shaped female end. An adhesive spread on

the male section secures the joint. A coupling with tapers at each side is used to join two

lengths of tapered male pipe ends. A straight coupling (used with straight pipe ends) with

no taper is also available.

Butt and Strap Joint

This type of joint, illustrated in Fig. 2.19, is made by squaring and deburring each end of

the pipes to be joined. The ends are aligned and then the outside is wrapped with layers of

glass mat and cloth saturated with resin. The width of the wrapping depends on the pressure

rating of the pipe.

Elastomeric Compression Joint

The joint shall conform to ASTM D-3212.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.