Page 89 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 89

PIPING

PIPING 2.39

HINGED CLAMP

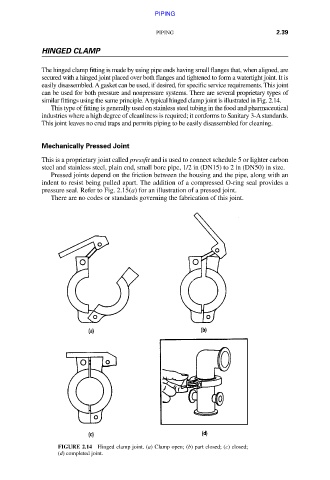

The hinged clamp fitting is made by using pipe ends having small flanges that, when aligned, are

secured with a hinged joint placed over both flanges and tightened to form a watertight joint. It is

easily disassembled. A gasket can be used, if desired, for specific service requirements. This joint

can be used for both pressure and nonpressure systems. There are several proprietary types of

similar fittings using the same principle. A typical hinged clamp joint is illustrated in Fig. 2.14.

This type of fitting is generally used on stainless steel tubing in the food and pharmaceutical

industries where a high degree of cleanliness is required; it conforms to Sanitary 3-A standards.

This joint leaves no crud traps and permits piping to be easily disassembled for cleaning.

Mechanically Pressed Joint

This is a proprietary joint called pressfit and is used to connect schedule 5 or lighter carbon

steel and stainless steel, plain end, small bore pipe, 1/2 in (DN15) to 2 in (DN50) in size.

Pressed joints depend on the friction between the housing and the pipe, along with an

indent to resist being pulled apart. The addition of a compressed O-ring seal provides a

pressure seal. Refer to Fig. 2.15(a) for an illustration of a pressed joint.

There are no codes or standards governing the fabrication of this joint.

FIGURE 2.14 Hinged clamp joint. (a) Clamp open; (b) part closed; (c) closed;

(d) completed joint.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.