Page 84 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 84

PIPING

2.34 CHAPTER TWO

FIGURE 2.10 Typical mechanical joint.

Grooved

There are two pipe-end preparations acceptable for a grooved joint: roll grooving

(shoulder) and cut grooving. Roll grooves are used when the pipe is too thin to have a

groove cut into it.

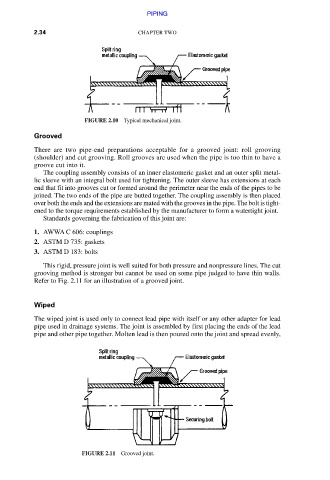

The coupling assembly consists of an inner elastomeric gasket and an outer split metal-

lic sleeve with an integral bolt used for tightening. The outer sleeve has extensions at each

end that fit into grooves cut or formed around the perimeter near the ends of the pipes to be

joined. The two ends of the pipe are butted together. The coupling assembly is then placed

over both the ends and the extensions are mated with the grooves in the pipe. The bolt is tight-

ened to the torque requirements established by the manufacturer to form a watertight joint.

Standards governing the fabrication of this joint are:

1. AWWA C 606: couplings

2. ASTM D 735: gaskets

3. ASTM D 183: bolts

This rigid, pressure joint is well suited for both pressure and nonpressure lines. The cut

grooving method is stronger but cannot be used on some pipe judged to have thin walls.

Refer to Fig. 2.11 for an illustration of a grooved joint.

Wiped

The wiped joint is used only to connect lead pipe with itself or any other adapter for lead

pipe used in drainage systems. The joint is assembled by first placing the ends of the lead

pipe and other pipe together. Molten lead is then poured onto the joint and spread evenly,

FIGURE 2.11 Grooved joint.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.