Page 83 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 83

PIPING

PIPING 2.33

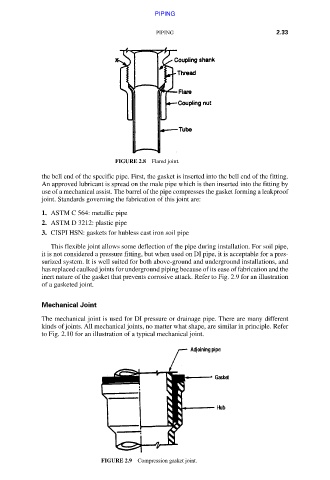

FIGURE 2.8 Flared joint.

the bell end of the specific pipe. First, the gasket is inserted into the bell end of the fitting.

An approved lubricant is spread on the male pipe which is then inserted into the fitting by

use of a mechanical assist. The barrel of the pipe compresses the gasket forming a leakproof

joint. Standards governing the fabrication of this joint are:

1. ASTM C 564: metallic pipe

2. ASTM D 3212: plastic pipe

3. CISPI HSN: gaskets for hubless cast iron soil pipe

This flexible joint allows some deflection of the pipe during installation. For soil pipe,

it is not considered a pressure fitting, but when used on DI pipe, it is acceptable for a pres-

surized system. It is well suited for both above-ground and underground installations, and

has replaced caulked joints for underground piping because of its ease of fabrication and the

inert nature of the gasket that prevents corrosive attack. Refer to Fig. 2.9 for an illustration

of a gasketed joint.

Mechanical Joint

The mechanical joint is used for DI pressure or drainage pipe. There are many different

kinds of joints. All mechanical joints, no matter what shape, are similar in principle. Refer

to Fig. 2.10 for an illustration of a typical mechanical joint.

FIGURE 2.9 Compression gasket joint.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.