Page 85 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 85

PIPING

PIPING 2.35

or wiped, around the pipe with a handheld pad until the minimum thickness is reached.

There shall be a minimum covered surface on each side of the joint of not less than 3/4 in,

and the added lead shall be a minimum of 3/8-in thick at the thickest part.

There are no recognized standards that govern the fabrication of the wiped joint.

Requirements are usually provided in plumbing codes.

This is a rigid, nonpressure joint. Since lead pipe is rarely encountered in modern drain-

age systems, there are few experienced mechanics capable of making up this joint.

Burned

The burned joint is used only to connect lead pipe to itself. It is made by flaring one end of

a pipe larger than the outside diameter of the other pipe to be joined. The two pipes are then

brought together with the ends overlapping. Heat is applied evenly around the perimeter,

melting the overlapping edges and fusing them together.

There are no recognized standards that govern the fabrication of the burned joint. This

is a rigid, nonpressure joint. Since lead pipe is rarely encountered in modern drainage

systems, there are few experienced mechanics capable of making up this joint.

WELDING

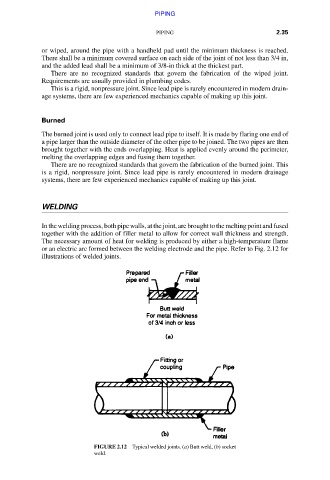

In the welding process, both pipe walls, at the joint, are brought to the melting point and fused

together with the addition of filler metal to allow for correct wall thickness and strength.

The necessary amount of heat for welding is produced by either a high-temperature flame

or an electric arc formed between the welding electrode and the pipe. Refer to Fig. 2.12 for

illustrations of welded joints.

FIGURE 2.12 Typical welded joints. (a) Butt weld, (b) socket

weld.

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.