Page 231 - Facility Piping Systems Handbook for Industrial, Commercial, and Healthcare Facilities

P. 231

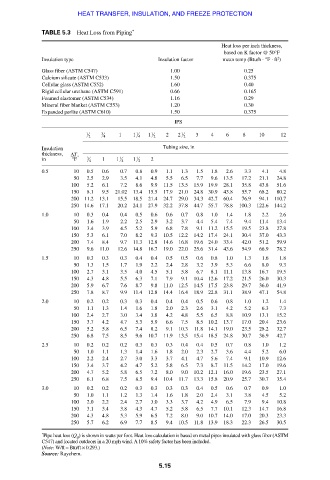

HEAT TRANSFER, INSULATION, AND FREEZE PROTECTION

TABLE 5.3 Heat Loss from Piping *

Heat loss per inch thickness,

based on K factor @ 50°F

Insulation type Insulation factor mean temp (Btu/h ⋅ °F ⋅ ft ) 2

Glass fiber (ASTM C547) 1.00 0.25

Calcium silicate (ASTM C533) 1.50 0.375

Cellular glass (ASTM C552) 1.60 0.40

Rigid cellular urethane (ASTM C591) 0.66 0.165

Foamed elastomer (ASTM C534) 1.16 0.29

Mineral fiber blanket (ASTM C553) 1.20 0.30

Expanded perlite (ASTM C610) 1.50 0.375

IPS

1 2 3 4 1 1 1 4 1 1 2 2 2 1 2 3 4 6 8 10 12

Insulation Tubing size, in

thickness, ΔT,

in °F 3 4 1 1 1 4 1 1 2 2

0.5 10 0.5 0.6 0.7 0.8 0.9 1.1 1.3 1.5 1.8 2.6 3.3 4.1 4.8

50 2.5 2.9 3.5 4.1 4.8 5.5 6.5 7.7 9.6 13.5 17.2 21.1 24.8

100 5.2 6.1 7.2 8.6 9.9 11.5 13.5 15.9 19.9 28.1 35.8 43.8 51.6

150 8.1 9.5 21.02 13.4 15.5 17.9 21.0 24.8 30.9 43.8 55.7 68.2 80.2

200 11.2 13.1 15.5 18.5 21.4 24.7 29.0 34.3 42.7 60.4 76.9 94.1 110.7

250 14.6 17.1 20.2 24.1 27.9 32.2 37.8 44.7 55.7 78.8 100.3 122.6 144.2

1.0 10 0.3 0.4 0.4 0.5 0.6 0.6 0.7 0.8 1.0 1.4 1.8 2.2 2.6

50 1.6 1.9 2.2 2.5 2.9 3.2 3.7 4.4 5.4 7.4 9.4 11.4 13.4

100 3.4 3.9 4.5 5.2 5.9 6.8 7.8 9.1 11.2 15.5 19.5 23.8 27.8

150 5.3 6.1 7.0 8.2 9.3 10.5 12.2 14.2 17.4 24.1 30.4 37.0 43.3

200 7.4 8.4 9.7 11.3 12.8 14.6 16.8 19.6 24.0 33.4 42.0 51.2 59.9

250 9.6 11.0 12.6 14.8 16.7 19.0 22.0 25.6 31.4 43.6 54.9 66.9 78.2

1.5 10 0.3 0.3 0.3 0.4 0.4 0.5 0.5 0.6 0.8 1.0 1.3 1.6 1.8

50 1.3 1.5 1.7 1.9 2.2 2.4 2.8 3.2 3.9 5.3 6.6 8.0 9.3

100 2.7 3.1 3.5 4.0 4.5 5.1 5.8 6.7 8.1 11.1 13.8 16.7 19.5

150 4.3 4.8 5.5 6.3 7.1 7.9 9.1 10.4 12.6 17.2 21.5 26.0 30.3

200 5.9 6.7 7.6 8.7 9.8 11.0 12.5 14.5 17.5 23.8 29.7 36.0 41.9

250 7.8 8.7 9.9 11.4 12.8 14.4 16.4 18.9 22.8 31.1 38.9 47.1 54.8

2.0 10 0.2 0.2 0.3 0.3 0.4 0.4 0.4 0.5 0.6 0.8 1.0 1.2 1.4

50 1.1 1.3 1.4 1.6 1.8 2.0 2.3 2.6 3.1 4.2 5.2 6.3 7.3

100 2.4 2.7 3.0 3.4 3.8 4.2 4.8 5.5 6.5 8.8 10.9 13.1 15.2

150 3.7 4.2 4.7 5.3 5.9 6.6 7.5 8.5 10.2 13.7 17.0 20.4 23.6

200 5.2 5.8 6.5 7.4 8.2 9.1 10.3 11.8 14.1 19.0 23.5 28.2 32.7

250 6.8 7.5 8.5 9.6 10.7 11.9 13.5 15.4 18.5 24.8 30.7 36.9 42.7

2.5 10 0.2 0.2 0.2 0.3 0.3 0.3 0.4 0.4 0.5 0.7 0.8 1.0 1.2

50 1.0 1.1 1.3 1.4 1.6 1.8 2.0 2.3 2.7 3.6 4.4 5.2 6.0

100 2.2 2.4 2.7 3.0 3.3 3.7 4.1 4.7 5.6 7.4 9.1 10.9 12.6

150 3.4 3.7 4.2 4.7 5.2 5.8 6.5 7.3 8.7 11.5 14.2 17.0 19.6

200 4.7 5.2 5.8 6.5 7.2 8.0 9.0 10.2 12.1 16.0 19.6 23.5 27.1

250 6.1 6.8 7.5 8.5 9.4 10.4 11.7 13.3 15.8 20.9 25.7 30.7 35.4

3.0 10 0.2 0.2 0.2 0.3 0.3 0.3 0.3 0.4 0.5 0.6 0.7 0.9 1.0

50 1.0 1.1 1.2 1.3 1.4 1.6 1.8 2.0 2.4 3.1 3.8 4.5 5.2

100 2.0 2.2 2.4 2.7 3.0 3.3 3.7 4.2 4.9 6.5 7.9 9.4 10.8

150 3.1 3.4 3.8 4.3 4.7 5.2 5.8 6.5 7.7 10.1 12.3 14.7 16.8

200 4.3 4.8 5.3 5.9 6.5 7.2 8.0 9.0 10.7 14.0 17.0 20.3 23.3

250 5.7 6.2 6.9 7.7 8.5 9.4 10.5 11.8 13.9 18.3 22.3 26.5 30.5

*

Pipe heat loss (Q B ) is shown in watts per foot. Heat loss calculation is based on metal pipes insulated with glass fiber (ASTM

C547) and located outdoors in a 20 mph wind. A 10% safety factor has been included.

(Note: W/ft = Btu/ft × 0.293.)

Source: Raychem.

5.15

Downloaded from Digital Engineering Library @ McGraw-Hill (www.accessengineeringlibrary.com)

Copyright © 2009 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.