Page 202 - Failure Analysis Case Studies II

P. 202

187

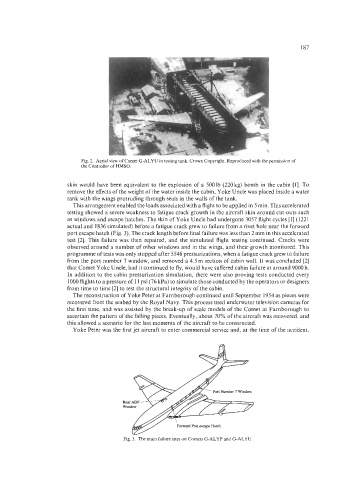

Fig. 2. Aerial view of Comet G-ALYU in testing tank. Crown Copyright. Reproduced with the permission of

the Controller of HMSO.

skin would have been equivalent to the explosion of a 5001b (220kg) bomb in the cabin [l]. To

remove the effects of the weight of the water inside the cabin, Yoke Uncle was placed inside a water

tank with the wings protruding through seals in the walls of the tank.

This arrangement enabled the loads associated with a flight to be applied in 5 min. This accelerated

testing showed a severe weakness to fatigue crack growth in the aircraft skin around cut-outs such

as windows and escape hatches. The skin of Yoke Uncle had undergone 3057 flight cycles [l] (1221

actual and 1836 simulated) before a fatigue crack grew to failure from a rivet hole near the forward

port escape hatch (Fig. 3). The crack length before final failure was less than 2 mm in this accelerated

test [2]. This failure was then repaired, and the simulated flight testing continued. Cracks were

observed around a number of other windows and in the wings, and their growth monitored. This

programme of tests was only stopped after 5546 pressurizations, when a fatigue crack grew to failure

from the port number 7 window, and removed a 4.5 m section of cabin wall. It was concluded [2]

that Comet Yoke Uncle, had it continued to fly, would have suffered cabin failure at around 9000 h.

In addition to the cabin pressurization simulation, there were also proving tests conducted every

1000 flights to a pressure of 11 psi (76 kPa) to simulate those conducted by the operators or designers

from time to time [2] to test the structural integrity of the cabin.

The reconstruction of Yoke Peter at Farnborough continued until September 1954 as pieces were

recovered from the seabed by the Royal Navy. This process used underwater television cameras for

the first time, and was assisted by the break-up of scale models of the Comet at Farnborough to

ascertain the pattern of the falling pieces. Eventually, about 70% of the aircraft was recovered, and

this allowed a scenario for the last moments of the aircraft to be constructed.

Yoke Peter was the first jet aircraft to enter commercial service and, at the time of the accident,

Port Number I Window

Forward Port escape Hatch

W

Fig. 3. The main failure sites on Comets G-ALYP and G-ALYU.