Page 211 - Failure Analysis Case Studies II

P. 211

196

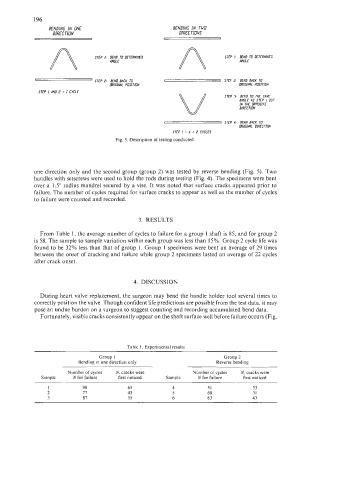

BENDING IN ON€ BENDING IN TM

DIREC TIUN DIRECTIONS

I STEP a BEND BACK ro I 1 STEP BEND BACK TO

GWGIML POSITION ORIGINAL POSITION

STEP I AND 2 = I CYCLE

SrCP 3 BEND TO 1s SAW

ANGLE AS STEP 1 BUT

IN TIC LPPOSITE

DIRCCTION

I STEP 4, BEND BACK TO

ORIGINAL DIRCCTION

STLP 1 - 4 = 2 CYCLES

Fig. 5. Description of testing conducted.

one direction only and the second group (group 2) was tested by reverse bending (Fig. 5). Two

handles with setscrews were used to hold the rods during testing (Fig. 4). The specimens were bent

over a 1.5” radius mandrel secured by a vise. It was noted that surface cracks appeared prior to

failure. The number of cycles required for surface cracks to appear as well as the number of cycles

to failure were counted and recorded.

3. RESULTS

From Table 1, the average number of cycles to failure for a group 1 shaft is 85, and for group 2

is 58. The sample to sample variation within each group was less than 15%. Group 2 cycle life was

found to be 32% less than that of group 1. Group 1 specimens were bent an average of 29 times

between the onset of cracking and failure while group 2 specimens lasted an average of 22 cycles

after crack onset.

4. DISCUSSION

During heart valve replacement, the surgeon may bend the handle holder tool several times to

correctly position the valve. Though confident life predictions are possible from the test data, it may

pose an undue burden on a surgeon to suggest counting and recording accumulated bend data.

Fortunately, visible cracks consistently appear on the shaft surface well before failure occurs (Fig.

Table I. Experimental results

Group I Group 2

Bending in one direction only Reverse bending

Number of cycles N, cracks were Number of cycles N, cracks were

Sample N for failure first noticed Sample N for failure first noticed

I 90 65 4 51 33

2 77 45 5 60 31

3 87 55 6 63 43