Page 400 - Failure Analysis Case Studies II

P. 400

3 84

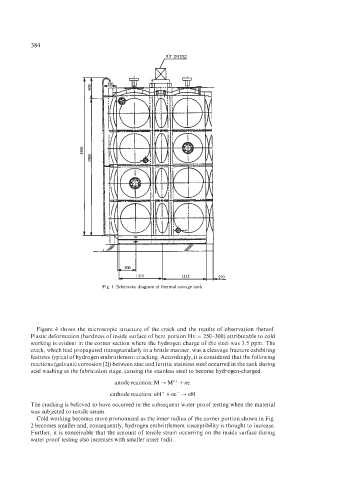

air pump

A-

Figure 4 shows the microscopic structure of the crack and the results of observation thereof.

Plastic deformation (hardness of inside surface of bent portion Hv = 25G300) attributable to cold

working is evident in the corner section where the hydrogen charge of the steel was 3.5 ppm. The

crack, which had propagated transgranularly in a brittle manner, was a cleavage fracture exhibiting

features typical of hydrogen embrittlement cracking. Accordingly, it is considered that the following

reactions (galvanic corrosion [2]) between zinc and ferritic stainless steel occurred in the tank during

acid washing at the fabrication stage, causing the stainless steel to become hydrogen-charged.

anode reaction: M + M”+ +ne

cathode reaction: nH+ +ne- -+ nH

The cracking is believed to have occurred in the subsequent water proof testing when the material

was subjected to tensile strain.

Cold working becomes more pronounced as the inner radius of the corner portion shown in Fig.

2 becomes smaller and, consequently, hydrogen embrittlement susceptibility is thought to increase.

Further, it is conceivable that the amount of tensile strain occurring on the inside surface during

water proof testing also increases with smaller inner radii.