Page 412 - Failure Analysis Case Studies II

P. 412

3 96

operation, termed delamination, is one of the qualitative indication of the decrease in ductility.

The fresh fracture surfaces were observed to be shiny, indicating the possibility of HE. No other

distinctive features were observed on the surfaces of failed wire rods.

The present investigation was carried out to confirm embrittlement either due to metallurgical

reasons or due to the presence of H. An attempt has also been made in this investigation to identify

HE by means of AE monitoring during delayed cracking experiment.

3. Experimental details

Metallographic examinations, after polishing with diamond paste in the final stage, in the

unetched and etched condition, were carried out on the longitudinal and transverse cross sections

of the wire. The failed surfaces were examined with the help of a scanning electron microscope

(S.E.M.) equipped with EDX facility.

Delayed cracking tests were conducted on partially split wire samples, by hanging a dead weight

(800 g), resulting in approximately 70% of the yield stress of the material, to one of the split ends.

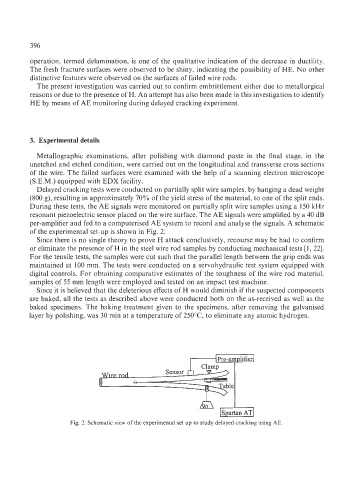

During these tests, the AE signals were monitored on partially split wire samples using a 150 kHz

resonant piezoelectric sensor placed on the wire surface. The AE signals were amplified by a 40 dB

per-amplifier and fed to a computerised AE system to record and analyse the signals. A schematic

of the experimental set-up is shown in Fig. 2.

Since there is no single theory to prove H attack conclusively, recourse may be had to confirm

or eliminate the presence of H in the steel wire rod samples by conducting mechanical tests [ 1,221.

For the tensile tests, the samples were cut such that the parallel length between the grip ends was

maintained at 100 mm. The tests were conducted on a servohydraulic test system equipped with

digital controls. For obtaining comparative estimates of the toughness of the wire rod material,

samples of 55 mm length were employed and tested on an impact test machine.

Since it is believed that the deleterious effects of H would diminish if the suspected components

are baked, all the tests as described above were conducted both on the as-received as well as the

baked specimens. The baking treatment given to the specimens, after removing the galvanised

layer by polishing, was 30 min at a temperature of 25OoC, to eliminate any atomic hydrogen.

Fig. 2. Schematic view of the experimental set up to study delayed cracking using AE.