Page 443 - Failure Analysis Case Studies II

P. 443

426

I Casing I

I!

Shaft

Original Design

I I Casing I

Shaft

New Design

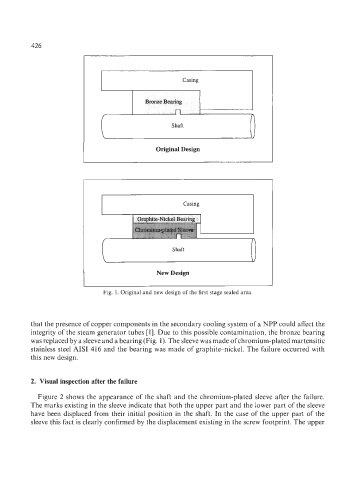

Fig. 1. Original and new design of the first stage sealed area.

that the presence of copper components in the secondary cooling system of a NPP could affect the

integrity of the steam generator tubes [l]. Due to this possible contamination, the bronze bearing

was replaced by a sleeve and a bearing (Fig. 1). The sleeve was made of chromium-plated martensitic

stainless steel AIS1 416 and the bearing was made of graphite-nickel. The failure occurred with

this new design.

2. Visual inspection after the failure

Figure 2 shows the appearance of the shaft and the chromium-plated sleeve after the failure.

The marks existing in the sleeve indicate that both the upper part and the lower part of the sleeve

have been displaced from their initial position in the shaft. In the case of the upper part of the

sleeve this fact is clearly confirmed by the displacement existing in the screw footprint. The upper