Page 139 - Fair, Geyer, and Okun's Water and wastewater engineering : water supply and wastewater removal

P. 139

JWCL344_ch03_061-117.qxd 8/17/10 7:48 PM Page 101

3.17 Well Construction 101

Pump discharge Cast-iron cover

Pump-house floor

Cement grout

Coarse sand

Float pipe

Inner casing

Gravel surcharge

Fine sand

Turbine pump

Outer casing

Concrete in bags

Hardpan

Fine sand

Limit of excavation

Aquifer,

coarse sand

Well screen

and gravel

Gravel wall

Base plate

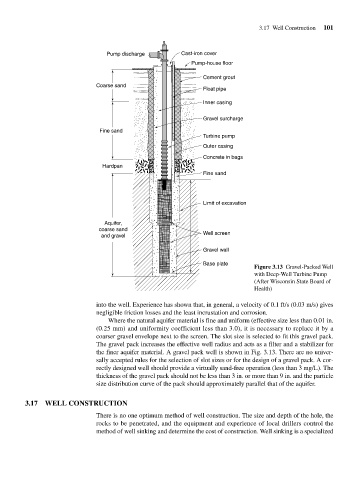

Figure 3.13 Gravel-Packed Well

with Deep-Well Turbine Pump

(After Wisconsin State Board of

Health)

into the well. Experience has shown that, in general, a velocity of 0.1 ft/s (0.03 m/s) gives

negligible friction losses and the least incrustation and corrosion.

Where the natural aquifer material is fine and uniform (effective size less than 0.01 in.

(0.25 mm) and uniformity coefficient less than 3.0), it is necessary to replace it by a

coarser gravel envelope next to the screen. The slot size is selected to fit this gravel pack.

The gravel pack increases the effective well radius and acts as a filter and a stabilizer for

the finer aquifer material. A gravel pack well is shown in Fig. 3.13. There are no univer-

sally accepted rules for the selection of slot sizes or for the design of a gravel pack. A cor-

rectly designed well should provide a virtually sand-free operation (less than 3 mg/L). The

thickness of the gravel pack should not be less than 3 in. or more than 9 in. and the particle

size distribution curve of the pack should approximately parallel that of the aquifer.

3.17 WELL CONSTRUCTION

There is no one optimum method of well construction. The size and depth of the hole, the

rocks to be penetrated, and the equipment and experience of local drillers control the

method of well sinking and determine the cost of construction. Well sinking is a specialized