Page 134 - Fiber Fracture

P. 134

FRACTURE CHARACTERISTICS OF SINGLE CRYSTAL AND EUTECTIC FIBERS 119

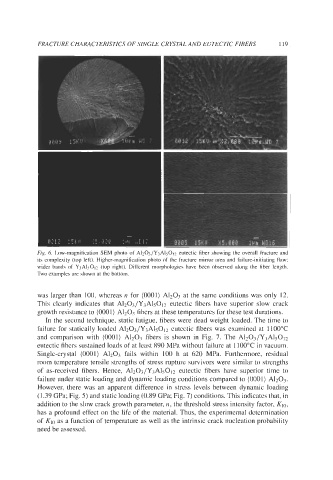

Fig. 6. Low-magnification SEM photo of A1203/Y3A15012 eutectic fiber showing the overall fracture and

its complexity (top left). Higher-magnification photo of the fracture mirror area and failure-initiating flaw;

wider bands of Y3A15012 (top right). Different morphologies have been observed along the fiber length.

Two examples are shown at the bottom.

was larger than 100, whereas n for (0001) A1203 at the same conditions was only 12.

This clearly indicates that A1203/Y3A15012 eutectic fibers have superior slow crack

growth resistance to (0001) A1203 fibers at these temperatures for these test durations.

In the second technique, static fatigue, fibers were dead weight loaded. The time to

failure for statically loaded A1203/Y3A15012 eutectic fibers was examined at 1100°C

and comparison with (0001) A1203 fibers is shown in Fig. 7. The A1203/Y3A15012

eutectic fibers sustained loads of at least 890 MPa without failure at 1100°C in vacuum.

Single-crystal (0001) A1203 fails within 100 h at 620 MPa. Furthermore, residual

room temperature tensile strengths of stress rupture survivors were similar to strengths

of as-received fibers. Hence, A1203/Y3A15012 eutectic fibers have superior time to

failure under static loading and dynamic loading conditions compared to (0001) A1203.

However, there was an apparent difference in stress levels between dynamic loading

(1.39 GPa; Fig. 5) and static loading (0.89 GPa; Fig. 7) conditions. This indicates that, in

addition to the slow crack growth parameter, n, the threshold stress intensity factor, KIO,

has a profound effect on the life of the material. Thus, the experimental determination

of KIO as a function of temperature as well as the intrinsic crack nucleation probability

need be assessed.