Page 185 - Fiber Fracture

P. 185

170 J.G. Lavin

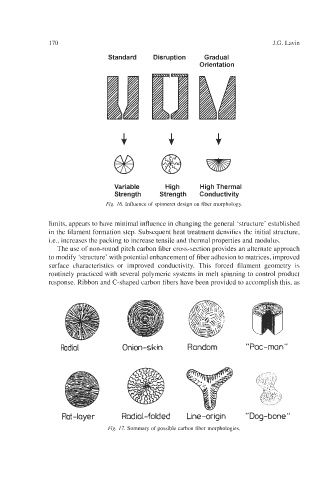

Standard Disruption Gradual

Orientation

J.

Variable High High Thermal

Strength Strength Conductivity

Fig. 16. Influence of spinneret design on fiber morphology.

limits, appears to have minimal influence in changing the general 'structure' established

in the filament formation step. Subsequent heat treatment densifies the initial structure,

i.e., increases the packing to increase tensile and thermal properties and modulus.

The use of non-round pitch carbon fiber cross-section provides an alternate approach

to modify 'structure' with potential enhancement of fiber adhesion to matrices, improved

surface characteristics or improved conductivity. This forced filament geometry is

routinely practiced with several polymeric systems in melt spinning to control product

response. Ribbon and C-shaped carbon fibers have been provided to accomplish this, as

Radial Onion-sk in Random " Pac -man "

Flat -layer Radial -folded Line-or igin "Dog- bone"

Fig. 17. Summary of possible carbon fiber morphologies.