Page 263 - Fiber Fracture

P. 263

246 K. Yoshida

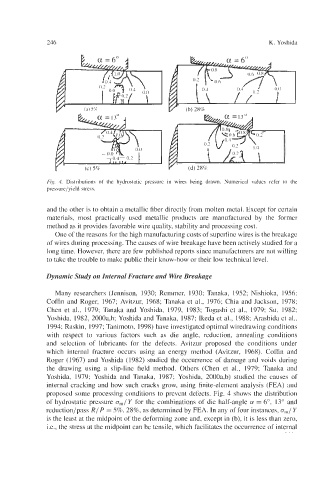

Fig. 4. Distributions of the hydrostatic pressure in wires being drawn. Numerical values refer to the

pressure/yield stress.

and the other is to obtain a metallic fiber directly from molten metal. Except for certain

materials, most practically used metallic products are manufactured by the former

method as it provides favorable wire quality, stability and processing cost.

One of the reasons for the high manufacturing costs of superfine wires is the breakage

of wires during processing. The causes of wire breakage have been actively studied for a

long time. However, there are few published reports since manufacturers are not willing

to take the trouble to make public their know-how or their low technical level.

Dynamic Study on Internal Fracture and Wire Breakage

Many researchers (Jennison, 1930; Remmer, 1930; Tanaka, 1952; Nishioka, 1956;

Coffin and Roger, 1967; Avitzur, 1968; Tanaka et a]., 1976; Chia and Jackson, 1978;

Chen et al., 1979; Tanaka and Yoshida, 1979, 1983; Togashi et al., 1979; Su, 1982;

Yoshida, 1982, 2000a,b; Yoshida and Tanaka, 1987; Ikeda et al., 1988; Arashida et al.,

1994; Raskin, 1997; Tanimoto, 1998) have investigated optimal wiredrawing conditions

with respect to various factors such as die angle, reduction, annealing conditions

and selection of lubricants for the defects. Avitzur proposed the conditions under

which internal fracture occurs using an energy method (Avitzur, 1968). Coffin and

Roger (1967) and Yoshida (1982) studied the occurrence of damage and voids during

the drawing using a slip-line field method. Others (Chen et al., 1979; Tanaka and

Yoshida, 1979; Yoshida and Tanaka, 1987; Yoshida, 2000a,b) studied the causes of

internal cracking and how such cracks grow, using finite-element analysis (FEA) and

proposed some processing conditions to prevent defects. Fig. 4 shows the distribution

of hydrostatic pressure a,/Y for the combinations of die half-angle a = 6", 13" and

reductionlpass RIP = 5%, 28%, as determined by FEA. In any of four instances, om/ Y

is the least at the midpoint of the deforming zone and, except in (b), it is less than zero,

Le., the stress at the midpoint can be tensile, which facilitates the occurrence of internal