Page 268 - Fiber Fracture

P. 268

FRACTURE OF SUPERFINE METALLIC WIRES 25 1

-60 ~ 140

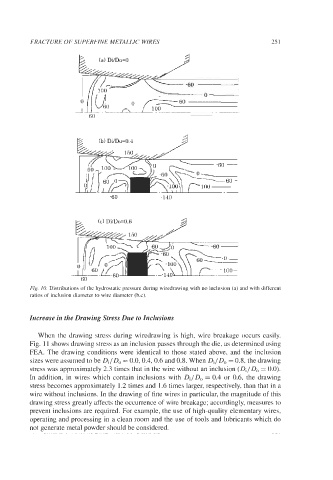

Fig. IO. Distributions of the hydrostatic pressure during wiredrawing with no inclusion (a) and with different

ratios of inclusion diameter to wire diameter (b,c).

Increase in the Drawing Stress Due to Inclusions

When the drawing stress during wiredrawing is high, wire breakage occurs easily.

Fig. 11 shows drawing stress as an inclusion passes through the die, as determined using

FEA. The drawing conditions were identical to those stated above, and the inclusion

sizes were assumed to be DilD, = 0.0,0.4,0.6 and 0.8. When Di/D, = 0.8, the drawing

stress was approximately 2.3 times that in the wire without an inclusion (Di/D, = 0.0).

In addition, in wires which contain inclusions with Di/D, = 0.4 or 0.6, the drawing

stress becomes approximately 1.2 times and 1.6 times larger, respectively, than that in a

wire without inclusions. In the drawing of fine wires in particular, the magnitude of this

drawing stress greatly affects the occurrence of wire breakage; accordingly, measures to

prevent inclusions are required. For example, the use of high-quality elementary wires,

operating and processing in a clean room and the use of tools and lubricants which do

not generate metal powder should be considered.