Page 266 - Fiber Fracture

P. 266

FRACTURE OF SUPERFINE METALLIC WIRES 249

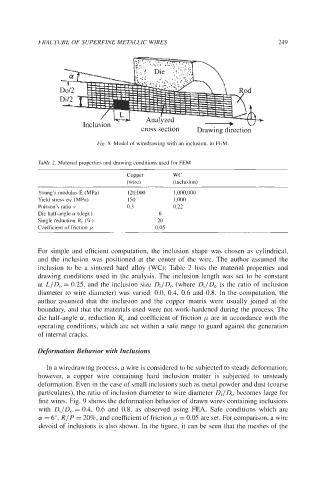

Fig. 8. Model of wiredrawing with an inclusion, in FEM.

Table 2. Material properties and drawing conditions used for FEM

Copper WC

(wire) (inclusion)

Young's modulus E (MPa) 120,000 1,000,000

Yield stress cry (MPa) 150 1,000

Poisson's ratio IJ 0.3 0.22

Die half-angle a (degr.) 6

Single reduction Re (%) 20

Coefficient of friction p 0.05

For simple and efficient computation, the inclusion shape was chosen as cylindrical,

and the inclusion was positioned at the center of the wire. The author assumed the

inclusion to be a sintered hard alloy (WC); Table 2 lists the material properties and

drawing conditions used in the analysis. The inclusion length was set to be constant

at LIDo = 0.25, and the inclusion size Di/D, (where DilD, is the ratio of inclusion

diameter to wire diameter) was varied: 0.0, 0.4, 0.6 and 0.8. In the computation, the

author assumed that the inclusion and the copper matrix were usually joined at the

boundary, and that the materials used were not work-hardened during the process. The

die half-angle a, reduction Re and coefficient of friction p are in accordance with the

operating conditions, which are set within a safe range to guard against the generation

of internal cracks.

Deformation Behavior with Inclusions

In a wiredrawing process, a wire is considered to be subjected to steady deformation;

however, a copper wire containing hard inclusion matter is subjected to unsteady

deformation. Even in the case of small inclusions such as metal powder and dust (coarse

particulates), the ratio of inclusion diameter to wire diameter DJD, becomes large for

fine wires. Fig. 9 shows the deformation behavior of drawn wires containing inclusions

with Di/D, = 0.4, 0.6 and 0.8, as observed using FEA. Safe conditions which are

a! = 6", R/ P = 20%, and coefficient of friction p = 0.05 are set. For comparison, a wire

devoid of inclusions is also shown. In the figure, it can be seen that the meshes of the