Page 271 - Fiber Fracture

P. 271

254 K. Yoshida

drawing stress was high and the wire could not tolerate the stress generated under this

condition, the inclusion could not pass through the die and the wire broke.

FILAMENT BREAKAGE DURING COMPOSITE WIREDRAWING

In the fabrication technology of various composite wires, internal fracture and

filament breakage of the wire are fatal to the wire quality. The detection of wire defects

is extremely difficult, since most of the defects exist inside the wire and cannot be

detected by surface observation. In this study, defects of copper-clad nickel wire and

composite wires such as Cu-NbTi superconducting wire are detected during the drawing

process through acoustic emission (AE) measurement, and also the applicability of these

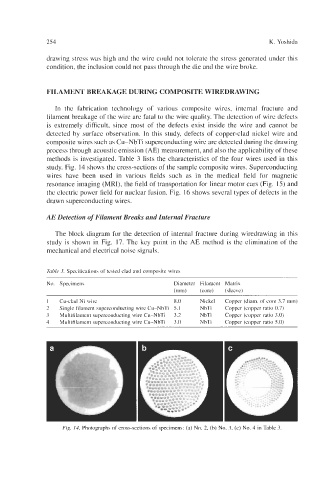

methods is investigated. Table 3 lists the characteristics of the four wires used in this

study. Fig. 14 shows the cross-sections of the sample composite wires. Superconducting

wires have been used in various fields such as in the medical field for magnetic

resonance imaging (MRI), the field of transportation for linear motor cars (Fig. 15) and

the electric power field for nuclear fusion. Fig. 16 shows several types of defects in the

drawn superconducting wires.

AE Detection of Filament Breaks and Internal Fracture

The block diagram for the detection of internal fracture during wiredrawing in this

study is shown in Fig. 17. The key point in the AE method is the elimination of the

mechanical and electrical noise signals.

Table 3. Specifications of tested clad and composite wires

~~ ~~

No. Specimens Diameter Filament Matrix

(mm) (core) (sleeve)

1 Cu-clad Ni wire 8.0 Nickel Copper (diam. of core 3.7 mm)

2 Single filament superconducting wire Cu-NbTi 5.1 NbTi Copper (copper ratio 0.7)

3 Multifilament superconducting wire Cu-NbTi 3.2 NbTi Copper (copper ratio 3.0)

4 Multifilament superconducting wire Cu-NbTi 3.0 NbTi Copper (copper ratio 5.0)

Fig. 14. Photographs of cross-sections of specimens: (a) No. 2, (b) No. 3, (c) No. 4 in Table 3