Page 199 - Finite Element Modeling and Simulations with ANSYS Workbench

P. 199

184 Finite Element Modeling and Simulation with ANSYS Workbench

a

b L

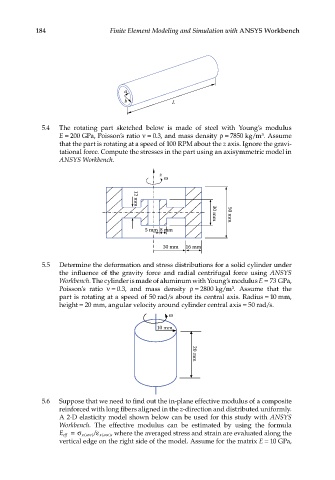

5.4 The rotating part sketched below is made of steel with Young’s modulus

E = 200 GPa, Poisson’s ratio ν = 0.3, and mass density ρ = 7850 kg/m . Assume

3

that the part is rotating at a speed of 100 RPM about the z axis. Ignore the gravi-

tational force. Compute the stresses in the part using an axisymmetric model in

ANSYS Workbench.

z

12 mm

5 mm 8 mm 30 mm 50 mm

30 mm 16 mm

5.5 Determine the deformation and stress distributions for a solid cylinder under

the influence of the gravity force and radial centrifugal force using ANSYS

Workbench. The cylinder is made of aluminum with Young’s modulus E = 73 GPa,

Poisson’s ratio ν = 0.3, and mass density ρ = 2800 kg/m . Assume that the

3

part is rotating at a speed of 50 rad/s about its central axis. Radius = 10 mm,

height = 20 mm, angular velocity around cylinder central axis = 50 rad/s.

10 mm 20 mm

5.6 Suppose that we need to find out the in-plane effective modulus of a composite

reinforced with long fibers aligned in the z-direction and distributed uniformly.

A 2-D elasticity model shown below can be used for this study with ANSYS

Workbench. The effective modulus can be estimated by using the formula

x ave ε/ x ave), where the averaged stress and strain are evaluated along the

E eff =σ ( ) (

vertical edge on the right side of the model. Assume for the matrix E = 10 GPa,