Page 110 - Flexible Robotics in Medicine

P. 110

Flexible steerable manipulator utilizing complementary configuration 95

Key features Comments on relevance

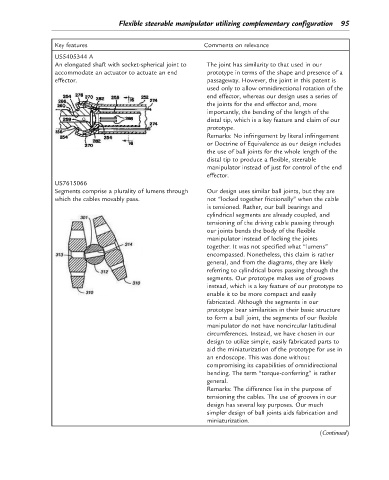

US5405344 A

An elongated shaft with socket-spherical joint to The joint has similarity to that used in our

accommodate an actuator to actuate an end prototype in terms of the shape and presence of a

effector. passageway. However, the joint in this patent is

used only to allow omnidirectional rotation of the

end effector, whereas our design uses a series of

the joints for the end effector and, more

importantly, the bending of the length of the

distal tip, which is a key feature and claim of our

prototype.

Remarks: No infringement by literal infringement

or Doctrine of Equivalence as our design includes

the use of ball joints for the whole length of the

distal tip to produce a flexible, steerable

manipulator instead of just for control of the end

effector.

US7615066

Segments comprise a plurality of lumens through Our design uses similar ball joints, but they are

which the cables movably pass. not “locked together frictionally” when the cable

is tensioned. Rather, our ball bearings and

cylindrical segments are already coupled, and

tensioning of the driving cable passing through

our joints bends the body of the flexible

manipulator instead of locking the joints

together. It was not specified what “lumens”

encompassed. Nonetheless, this claim is rather

general, and from the diagrams, they are likely

referring to cylindrical bores passing through the

segments. Our prototype makes use of grooves

instead, which is a key feature of our prototype to

enable it to be more compact and easily

fabricated. Although the segments in our

prototype bear similarities in their basic structure

to form a ball joint, the segments of our flexible

manipulator do not have noncircular latitudinal

circumferences. Instead, we have chosen in our

design to utilize simple, easily fabricated parts to

aid the miniaturization of the prototype for use in

an endoscope. This was done without

compromising its capabilities of omnidirectional

bending. The term “torque-conferring” is rather

general.

Remarks: The difference lies in the purpose of

tensioning the cables. The use of grooves in our

design has several key purposes. Our much

simpler design of ball joints aids fabrication and

miniaturization.

(Continued)