Page 449 - Flexible Robotics in Medicine

P. 449

Flexible drill manipulator utilizing different rolling sliding joints for transoral drilling 443

Table 19.4: Maximum force sustained by Goldrill prototypes.

Maximum resultant vector Force (mN) Standard deviation (mN)

Goldrill GR3 (with handle) 13,175 2220.7

Goldrill GR2 3171 331.82

Goldrill GE3 1978 49.34

Goldrill GE2 1160 318.32

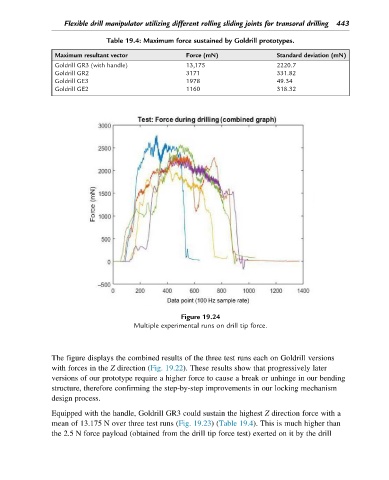

Figure 19.24

Multiple experimental runs on drill tip force.

The figure displays the combined results of the three test runs each on Goldrill versions

with forces in the Z direction (Fig. 19.22). These results show that progressively later

versions of our prototype require a higher force to cause a break or unhinge in our bending

structure, therefore confirming the step-by-step improvements in our locking mechanism

design process.

Equipped with the handle, Goldrill GR3 could sustain the highest Z direction force with a

mean of 13.175 N over three test runs (Fig. 19.23)(Table 19.4). This is much higher than

the 2.5 N force payload (obtained from the drill tip force test) exerted on it by the drill