Page 75 - Fluid Mechanics and Thermodynamics of Turbomachinery

P. 75

56 Fluid Mechanics, Thermodynamics of Turbomachinery

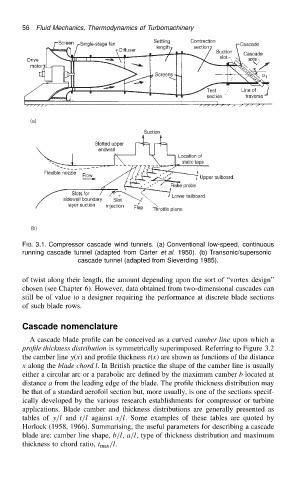

FIG. 3.1. Compressor cascade wind tunnels. (a) Conventional low-speed, continuous

running cascade tunnel (adapted from Carter et al. 1950). (b) Transonic/supersonic

cascade tunnel (adapted from Sieverding 1985).

of twist along their length, the amount depending upon the sort of “vortex design”

chosen (see Chapter 6). However, data obtained from two-dimensional cascades can

still be of value to a designer requiring the performance at discrete blade sections

of such blade rows.

Cascade nomenclature

A cascade blade profile can be conceived as a curved camber line upon which a

profile thickness distribution is symmetrically superimposed. Referring to Figure 3.2

the camber line y.x/ and profile thickness t.x/ are shown as functions of the distance

x along the blade chord l. In British practice the shape of the camber line is usually

either a circular arc or a parabolic arc defined by the maximum camber b located at

distance a from the leading edge of the blade. The profile thickness distribution may

be that of a standard aerofoil section but, more usually, is one of the sections specif-

ically developed by the various research establishments for compressor or turbine

applications. Blade camber and thickness distributions are generally presented as

tables of y/l and t/l against x/l. Some examples of these tables are quoted by

Horlock (1958, 1966). Summarising, the useful parameters for describing a cascade

blade are: camber line shape, b/l, a/l, type of thickness distribution and maximum

thickness to chord ratio, t max /l.