Page 151 - Fluid-Structure Interactions Slender Structure and Axial Flow (Volume 1)

P. 151

PIPES CONVEYING FLUID: LINEAR DYNAMICS I 133

3.5.6 Experiments

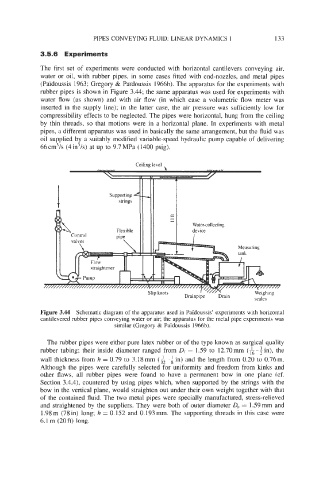

The first set of experiments were conducted with horizontal cantilevers conveying air,

water or oil, with rubber pipes, in some cases fitted with end-nozzles, and metal pipes

(Pai‘doussis 1963; Gregory & PaYdoussis 1966b). The apparatus for the experiments with

rubber pipes is shown in Figure 3.44; the same apparatus was used for experiments with

water flow (as shown) and with air flow (in which case a volumetric flow meter was

inserted in the supply line): in the latter case, the air pressure was sufficiently low for

compressibility effects to be neglected. The pipes were horizontal, hung from the ceiling

by thin threads, so that motions were in a horizontal plane. In experiments with metal

pipes, a different apparatus was used in basically the same arrangement, but the fluid was

oil supplied by a suitably modified variable-speed hydraulic pump capable of delivering

66cm’/s (4in’/s) at up to 9.7MPa (1400 psig).

Ceiling level

u:

. ”’ b

Supporting

strings

Water-collecting

device

I

Measuring

m

n.. 1 .

allp KIlOIS

Drainpipe Drain

scales

Figure 3.44 Schematic diagram of the apparatus used in Paldoussis’ experiments with horizontal

cantilevered rubber pipes conveying water or air; the apparatus for the metal pipe experiments was

similar (Gregory & Pai’doussis 1966b).

The rubber pipes were either pure latex rubber or of the type known as surgical quality

rubber tubing; their inside diameter ranged from Di = 1.59 to 12.70mm (k- in), the

wall thickness from h = 0.79 to 3.18 mm (& - $ in) and the length from 0.20 to 0.76 m.

Although the pipes were carefully selected for uniformity and freedom from kinks and

other flaws, all rubber pipes were found to have a permanent bow in one plane (cf.

Section 3.4.4), countered by using pipes which, when supported by the strings with the

bow in the vertical plane, would straighten out under their own weight together with that

of the contained fluid. The two metal pipes were specially manufactured, stress-relieved

and straightened by the suppliers. They were both of outer diameter Do = 1.59 mm and

1.98 m (78 in) long; h = 0.152 and 0.193 mm. The supporting threads in this case were

6.1 m (20 ft) long.