Page 287 - Fluid-Structure Interactions Slender Structure and Axial Flow (Volume 1)

P. 287

268 SLENDER STRUCTURES AND AXIAL FLOW

the text, e.g. in connection with the stability of long pipelines on elastic foundations in

Section 3.7.

The most enduring benefit of this research, however, is in developing the fundamentals

and methods which are used in related topics involving axial-flow -structure interactions,

which do have engineering applications. For example, the dynamics of cylindrical bodies

in axial or annular flow and the dynamics of shells containing or immersed in axial flow,

covered in Volume 2, can be understood in simple terns, modelled mathematically and

solved by means of the work presented throughout Volume 1.

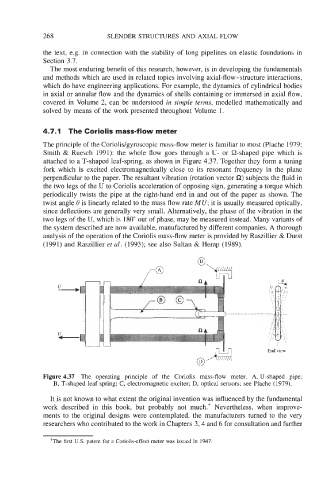

4.7.1 The Coriolis mass-flow meter

The principle of the Coriolis/gyroscopic mass-flow meter is familiar to most (Plache 1979;

Smith & Ruesch 1991): the whole flow goes through a U- or Q-shaped pipe which is

attached to a T-shaped leaf-spring, as shown in Figure 4.37. Together they form a tuning

fork which is excited electromagnetically close to its resonant frequency in the plane

perpendicular to the paper. The resultant vibration (rotation vector S2) subjects the fluid in

the two legs of the U to Coriolis acceleration of opposing sign, generating a torque which

periodically twists the pipe at the right-hand end in and out of the paper as shown. The

twist angle 0 is linearly related to the mass flow rate MU; it is usually measured optically,

since deflections are generally very small. Alternatively, the phase of the vibration in the

two legs of the U, which is 180" out of phase, may be measured instead. Many variants of

the system described are now available, manufactured by different companies. A thorough

analysis of the operation of the Coriolis mass-flow meter is provided by Raszillier & Durst

(1991) and Raszillier et al. (1993); see also Sultan & Hemp (1989).

. . . . . . .

End view

Figure 4.37 The operating principle of the Coriolis mass-flow meter. A, U-shaped pipe;

B, T-shaped leaf spring; C, electromagnetic exciter; D, optical sensors; see Plache (1979).

It is not known to what extent the original invention was influenced by the fundamental

work described in this book, but probably not much.? Nevertheless, when improve-

ments to the original designs were contemplated, the manufacturers turned to the very

researchers who contributed to the work in Chapters 3,4 and 6 for consultation and further

+The first U.S. patent for a Coriolis-effect meter was issued in 1947.