Page 502 - Fluid-Structure Interactions Slender Structure and Axial Flow (Volume 1)

P. 502

472 SLENDER STRUCTWS AND AXIAL FLOW

Embedded

metal strip

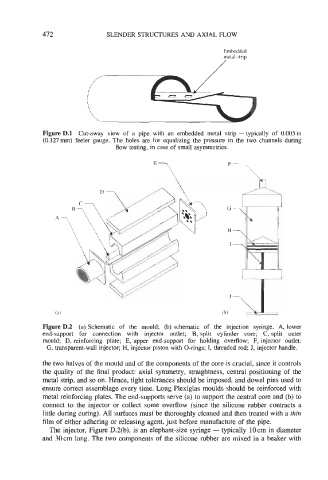

Figure D.l Cut-away view of a pipe with an embedded metal strip - typically of 0.005in

(0.127mm) feeler gauge. The holes are for equalizing the pressure in the two channels during

flow testing, in case of small asymmetries.

F- _4:

E?\

G

H

I

Figure D.2 (a) Schematic of the mould; (b) schematic of the injection syringe. A, lower

end-support for connection with injector outlet; B, split cylinder core; C, split outer

mould; D, reinforcing plate; E, upper end-support for holding overilow; F, injector outlet;

G, transparent-wall injector; H, injector piston with O-rings; I, threaded rod; J, injector handle.

the two halves of the mould and of the components of the core is crucial, since it controls

the quality of the final product: axial symmetry, straightness, central positioning of the

metal strip, and so on. Hence, tight tolerances should be imposed, and dowel pins used to

ensure correct assemblage every time. Long Plexiglas moulds should be reinforced with

metal reinforcing plates. The end-supports serve (a) to support the central core and (b) to

connect to the injector or collect some overflow (since the silicone rubber contracts a

little during curing). All surfaces must be thoroughly cleaned and then treated with a thin

film of either adhering or releasing agent, just before manufacture of the pipe.

The injector, Figure D.2(b), is an elephant-size syringe - typically IOcm in diameter

and 30cm long. The two components of the silicone rubber are mixed in a beaker with