Page 153 - Fluid mechanics, heat transfer, and mass transfer

P. 153

PUMPS 131

& Size and shape of the rotor also influences slip. & Pulsations are slight and may be eliminated by the

& Pressure: Increased pressure increases slip. use of helical gears.

& Liquid viscosity: Increased viscosity decreases slip. & They are valveless and can reverse flow. They are

relatively simple to maintain and rebuild.

& Pump speed: Slip is independent of speed.

& They are less sensitive to cavitation problems com-

. “For a rotary pump, flow is proportional to speed and

pared to centrifugal pumps.

almost independent of pressure differential.” True/

False? & Major disadvantage is their inability to resist erosion,

abrasion, and corrosion. Disadvantages include lim-

& True.

itations in the selection of materials of construction

. “ In a rotary pump, entrained gases will not have any

due to tight tolerances required. Since the gears

effect on liquid capacity.” True/False?

touch, the materials of construction should be dis-

& False.

similar, especially for low-viscosity liquids or poorly

. What are the attributes of a liquid ring pump? lubricated applications.

& A liquid ring pump is primarily a high efficiency & High shear is placed on the liquid.

centrifugal pump. & The fluid must be free from abrasives.

& Self-priming when pump casing is half filled.

& Gear pumps must be controlled through the control of

& Suitable for aerated fluids.

motor speed. Throttling the discharge is not an

& Impeller is radial type with straight vanes. acceptable means of control.

& For each type of liquid ring pump there is only one & They can be damaged if run dry.

impeller size. & Uneconomical for large flows.

. What is dead head speed? & These pumps are appropriate for use for high-pres-

& Pump speed required to overcome slip is known as sure and low-capacity applications.

dead head speed. & Even with limitations on operating speed, a relatively

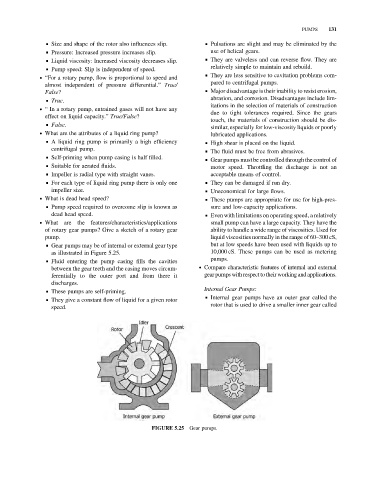

. What are the features/characteristics/applications small pump can have a large capacity. They have the

of rotary gear pumps? Give a sketch of a rotary gear ability to handle a wide range of viscosities. Used for

pump. liquid viscosities normally in the range of 60–300 cS,

& Gear pumps may be of internal or external gear type but at low speeds have been used with liquids up to

as illustrated in Figure 5.25. 10,000 cS. These pumps can be used as metering

pumps.

& Fluid entering the pump casing fills the cavities

between the gear teeth and the casing moves circum- . Compare characteristic features of internal and external

ferentially to the outer port and from there it gear pumpswithrespectto theirworking and applications.

discharges.

Internal Gear Pumps:

& These pumps are self-priming.

& Internal gear pumps have an outer gear called the

& They give a constant flow of liquid for a given rotor

rotor that is used to drive a smaller inner gear called

speed.

FIGURE 5.25 Gear pumps.