Page 157 - Fluid mechanics, heat transfer, and mass transfer

P. 157

PUMPS 135

& Plumbing: Connection size, material, and fitting. . What are the applications of rotary lobe pumps?

Suction side tubing size is critical to prevent cavita- & Rotary lobe. The rotary lobe pump is typically used

tion, which may occur when the tubing size is too as a mechanical booster operating in series with an

small to allow adequate flow of fluid to enter the oil-sealed piston or vane pump to boost pumping

pump. Cavitation can cause problems including ham- capacity at low pressures.

mer, flow variation, bubble formation, loss of prime, & This pump consists of two symmetrical two-lobe

and eventually pump damage.

rotors mounted on separate shafts in parallel, which

& Drive power: AC, DC, pneumatic, stepper, and

rotate in opposite directions to each other at high

mechanical. speeds.

& Flow control: Fixed, variable, and reversing. & As with a rotary claw pump, timing gears are used to

& Control source: Manual, electronic, and mechanical. synchronize the rotation of the lobes to provide

& Special requirements: Hazardous, sanitary, sterile, constant clearance between the two.

outdoor, and so on. & The number of lobes varies between one and five.

& In addition to the above, fluid characteristics, chem- . What are the salient features of a rotary bilobe pump?

ical compatibility (with pump wetted parts or fluid & Rotary bilobe pump consists of two symmetrical

path), viscosity, corrosive application, specific two-lobe rotors, each mounted on a separate shaft

gravity, suspended solids (percent and particle size), in parallel, which rotate in opposite direction to each

air sensitivity, crystallizing characteristics, shear other at high rotational speeds without making any

sensitivity, size, and price are to be given due contact or using any seal liquid.

consideration. & It uses timing gears to synchronize the rotation of the

. What precaution is required for pumping shear-sensi- lobes to provide constant clearance between the two.

tive fluids such as yeast? The clearances are kept to low levels to minimize

& Use lower speeds (100–400 rpm depending upon back slip of the fluid.

fluid being pumped). . What are the applications of rotary pumps with bilobe

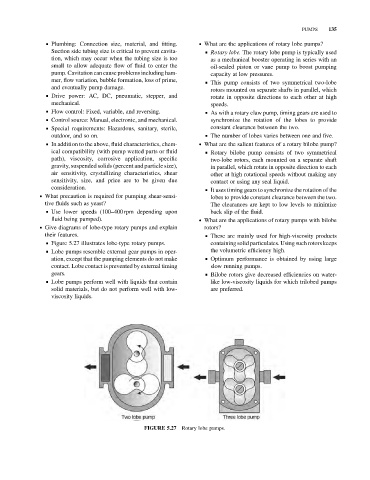

. Give diagrams of lobe-type rotary pumps and explain rotors?

their features. & These are mainly used for high-viscosity products

& Figure 5.27 illustrates lobe-type rotary pumps. containing solid particulates. Using such rotors keeps

& Lobe pumps resemble external gear pumps in oper- the volumetric efficiency high.

ation, except that the pumping elements do not make & Optimum performance is obtained by using large

contact. Lobe contact is prevented by external timing slow running pumps.

gears. & Bilobe rotors give decreased efficiencies on water-

& Lobe pumps perform well with liquids that contain like low-viscosity liquids for which trilobed pumps

solid materials, but do not perform well with low- are preferred.

viscosity liquids.

FIGURE 5.27 Rotary lobe pumps.