Page 155 - Fluid mechanics, heat transfer, and mass transfer

P. 155

PUMPS 133

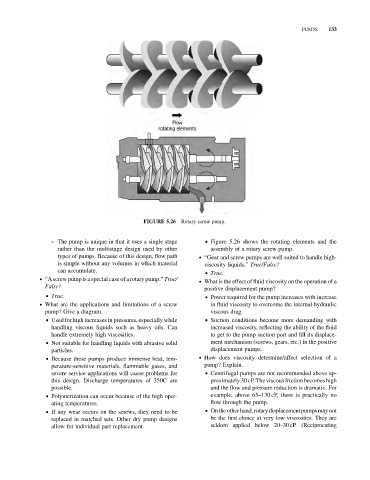

FIGURE 5.26 Rotary screw pump.

➢ The pump is unique in that it uses a single stage & Figure 5.26 shows the rotating elements and the

rather than the multistage design used by other assembly of a rotary screw pump.

types of pumps. Because of this design, flow path . “Gear and screw pumps are well suited to handle high-

is simple without any volumes in which material viscosity liquids.” True/False?

can accumulate. & True.

. “A screw pump is a special case of a rotary pump.” True/

. What is the effect of fluid viscosity on the operation of a

False?

positive displacement pump?

& True. & Power required for the pump increases with increase

. What are the applications and limitations of a screw in fluid viscosity to overcome the internal hydraulic

pump? Give a diagram. viscous drag.

& Used for high increases in pressures, especially while & Suction conditions become more demanding with

handling viscous liquids such as heavy oils. Can increased viscosity, reflecting the ability of the fluid

handle extremely high viscosities. to get to the pump suction port and fill its displace-

& Not suitable for handling liquids with abrasive solid ment mechanism (screws, gears, etc.) in the positive

particles. displacement pumps.

& Because these pumps produce immense heat, tem- . How does viscosity determine/affect selection of a

perature-sensitive materials, flammable gases, and pump? Explain.

severe service applications will cause problems for & Centrifugal pumps are not recommended above ap-

this design. Discharge temperatures of 350C are proximately 30 cP.Theviscous friction becomes high

possible. and the flow and pressure reduction is dramatic. For

& Polymerization can occur because of the high oper- example, above 65–130 cP, there is practically no

ating temperatures. flow through the pump.

& If any wear occurs on the screws, they need to be & Ontheotherhand,rotarydisplacementpumpsmaynot

replaced in matched sets. Other dry pump designs be the first choice at very low viscosities. They are

allow for individual part replacement. seldom applied below 20–30 cP. (Reciprocating