Page 162 - Fluid mechanics, heat transfer, and mass transfer

P. 162

140 PUMPS, EJECTORS, BLOWERS, AND COMPRESSORS

. What is an acid egg? & They meet aseptic production requirements and re-

& Egg-shaped container filled with a liquid that is quire a minimum of maintenance-related downtime.

pumped out by the use of compressed air, as in the They provide for sterile, precision filling of liquid

case of airlift pump. volumes with accuracies of 0.5% or better, drive with

variable speeds of 1–650 rpm and dispense volumes

& Used for pumping corrosive liquids such as acids.

from 10 mL to 10,000 L.

& Can be hand operated or arranged for semiautomatic

& Well suited to handle a wide range of fluid viscos-

or automatic operation.

ities and also particularly gentle on shear-sensitive

. What is a regenerative pump?

products such as cell cultures and bioreactor

& Regenerative pumps are essentially turbine pumps

constituents.

that employ a combination of mechanical impulse

& Also find applications in handling abrasive and cor-

and centrifugal force to produce high heads at low

rosive fluids.

flows.

& Other applications include dialysis machines, open

& Impellers used are high-speed type with close

heart bypass pump machines, and sewage sludge

clearances.

handling.

& Have many short radial passages milled on each side

& Fluid changeover is accomplished with a simple

at the periphery.

tubing change. No other parts of the pump come in

& Similar channels are milled in the mating surfaces of

contact of the fluid.

the casing.

& Suited for low-pressure operation (up to about 2 bar).

& Liquid is directed into the impeller passages and

. What are the desirable performance parameters for the

proceeds in a spiral pattern around the periphery,

tubing of peristaltic pumps?

passing alternatively from impeller to casing and

& Chemical compatibility: The tubing material must be

receiving successive impulses as it does so.

compatible with the pumped fluid to provide good

& Used for clean low-viscosity liquids (due to close

pumping performance, as well as safety. Many tubing

clearances).

suppliers provide chemical compatibility charts.

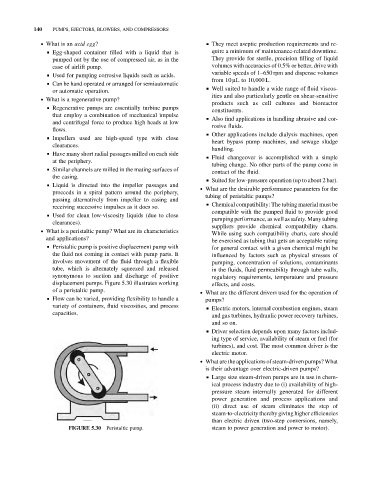

. What is a peristaltic pump? What are its characteristics

While using such compatibility charts, care should

and applications?

be exercised as tubing that gets an acceptable rating

& Peristaltic pump is positive displacement pump with

for general contact with a given chemical might be

the fluid not coming in contact with pump parts. It influenced by factors such as physical stresses of

involves movement of the fluid through a flexible pumping, concentration of solutions, contaminants

tube, which is alternately squeezed and released in the fluids, fluid permeability through tube walls,

synonymous to suction and discharge of positive regulatory requirements, temperature and pressure

displacement pumps. Figure 5.30 illustrates working effects, and costs.

of a peristaltic pump. . What are the different drivers used for the operation of

& Flow can be varied, providing flexibility to handle a

pumps?

variety of containers, fluid viscosities, and process & Electric motors, internal combustion engines, steam

capacities.

and gas turbines, hydraulic power recovery turbines,

and so on.

& Driver selection depends upon many factors includ-

ing type of service, availability of steam or fuel (for

turbines), and cost. The most common driver is the

electric motor.

. What are the applications of steam-driven pumps? What

is their advantage over electric-driven pumps?

& Large size steam-driven pumps are in use in chem-

ical process industry due to (i) availability of high-

pressure steam internally generated for different

power generation and process applications and

(ii) direct use of steam eliminates the step of

steam-to-electricity thereby giving higher efficiencies

than electric driven (two-step conversions, namely,

FIGURE 5.30 Peristaltic pump. steam to power generation and power to motor).