Page 164 - Fluid mechanics, heat transfer, and mass transfer

P. 164

142 PUMPS, EJECTORS, BLOWERS, AND COMPRESSORS

TABLE 5.7 Pressures Obtainable with Different Vacuum & The compression of the gas occurs in one or two

Producing Equipment impeller stages depending on the ultimate vacuum

Type of Equipment Pressure (Torr) required although for this service two-stage pumps

are generally required.

Reciprocating piston type Up to 1

& Water or some other incompressible fluid, called

Rotary piston type Up to 0.001

Two-lobe rotary Up to 0.0001 sealant liquid, is used as the sealant liquid. The

Steam jet ejectors sealant liquid, used for both sealing and cooling,

Single stage 100 can be any liquid that is compatible with the

Two stage 10 process having the following ranges of physical

Three stage 1 properties:

Five stage 0.05 ➢ Specific gravity: 0.5–1.5.

➢ Specific heat: 0.35–1.0, relative to that for water.

➢ Viscosity: 1 to 32 cP.

& Reciprocating piston vacuum pumps are generally

➢ Vapor pressure at operating temperature: Less

capable of vacuum to 1 Torr abs, rotary piston types

than or equal to vapor pressure of water at

can achieve vacuums of 0.001 Torr.

15 C.

. “A two-lobe rotary vacuum pump is capable of pro-

➢ Low-viscosity oils, glycols, and many solvents

ducing much higher vacuum compared to a rotary

such as toluene, methanol, ethanol, propanol, bu-

piston vacuum pump.” True/False?

tanol, and ethylbenzene can be used.

& True. Pressures attainable for a two-lobe rotary

& As the impeller rotates, a ring of liquid is formed

pumps are down to 0.0001 Torr while rotary piston

inside the pump casing developing centrifugal force

pumps can produce pressures down to 0.001 Torr.

that throws the liquid against the inside walls of the

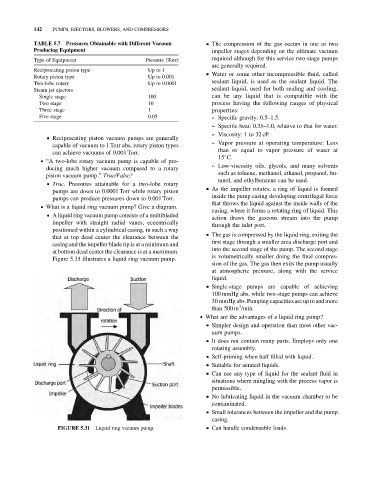

. What is a liquid ring vacuum pump? Give a diagram.

casing, where it forms a rotating ring of liquid. This

& A liquid ring vacuum pump consists of a multibladed

action draws the gaseous stream into the pump

impeller with straight radial vanes, eccentrically

through the inlet port.

positioned within a cylindrical casing, in such a way

& The gas is compressed by the liquid ring, exiting the

that at top dead center the clearance between the

first stage through a smaller area discharge port and

casing and the impeller blade tip is at a minimum and

into the second stage of the pump. The second stage

at bottom dead center the clearance is at a maximum.

is volumetrically smaller doing the final compres-

Figure 5.31 illustrates a liquid ring vacuum pump.

sion of the gas. The gas then exits the pump usually

at atmospheric pressure, along with the service

liquid.

& Single-stage pumps are capable of achieving

100 mmHg abs, while two-stage pumps can achieve

30 mmHg abs. Pumping capacities are up to and more

3

than 500 m /min.

. What are the advantages of a liquid ring pump?

& Simpler design and operation than most other vac-

uum pumps.

& It does not contain many parts. Employs only one

rotating assembly.

& Self-priming when half filled with liquid.

& Suitable for aerated liquids.

& Can use any type of liquid for the sealant fluid in

situations where mingling with the process vapor is

permissible.

& No lubricating liquid in the vacuum chamber to be

contaminated.

& Small tolerances between the impeller and the pump

casing.

FIGURE 5.31 Liquid ring vacuum pump. & Can handle condensable loads.