Page 190 - Fluid mechanics, heat transfer, and mass transfer

P. 190

MIXING

168

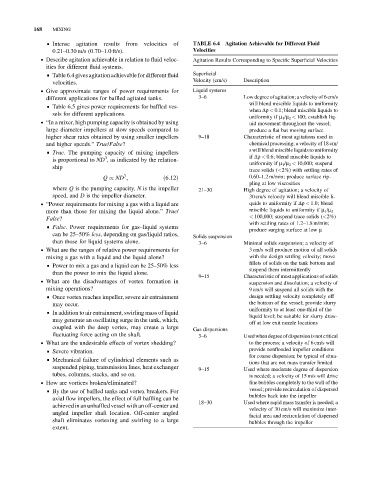

& Intense agitation results from velocities of TABLE 6.4 Agitation Achievable for Different Fluid

0.21–0.30 m/s (0.70–1.0 ft/s). Velocities

. Describe agitation achievable in relation to fluid veloc- Agitation Results Corresponding to Specific Superficial Velocities

ities for different fluid systems.

& Table 6.4 givesagitation achievable for different fluid Superficial

velocities. Velocity (cm/s) Description

. Give approximate ranges of power requirements for Liquid systems

different applications for baffled agitated tanks. 3–6 Low degree of agitation; a velocity of 6 cm/s

will blend miscible liquids to uniformity

& Table 6.5 gives power requirements for baffled ves-

when Dr < 0.1; blend miscible liquids to

sels for different applications.

uniformity if m 1 /m 2 < 100; establish liq-

. “In a mixer, high pumping capacity is obtained by using uid movement throughout the vessel;

large diameter impellers at slow speeds compared to produce a flat but moving surface

higher shear rates obtained by using smaller impellers 9–18 Characteristic of most agitations used in

and higher speeds.” True/False? chemical processing; a velocity of 18 cm/

s will blend miscible liquids to uniformity

& True. The pumping capacity of mixing impellers

3

is proportional to ND , as indicated by the relation- if Dr < 0.6; blend miscible liquids to

uniformity if m 1 /m 2 < 10,000; suspend

ship

trace solids (<2%) with settling rates of

3

Q / ND ; ð6:12Þ 0.60–1.2 m/min; produce surface rip-

pling at low viscosities

where Q is the pumping capacity, N is the impeller 21–30 High degree of agitation; a velocity of

speed, and D is the impeller diameter. 30 cm/s velocity will blend miscible li-

. “Power requirements for mixing a gas with a liquid are quids to uniformity if Dr < 1.0; blend

more than those for mixing the liquid alone.” True/ miscible liquids to uniformity if m 1 /m 2

False? < 100,000; suspend trace solids (<2%)

with settling rates of 1.2–1.8 m/min;

& False. Power requirements for gas–liquid systems

produce surging surface at low m

can be 25–50% less, depending on gas/liquid ratios, Solids suspension

than those for liquid systems alone. 3–6 Minimal solids suspension; a velocity of

. What are the ranges of relative power requirements for 3 cm/s will produce motion of all solids

mixing a gas with a liquid and the liquid alone? with the design settling velocity; move

fillets of solids on the tank bottom and

& Power to mix a gas and a liquid can be 25–50% less

suspend them intermittently

than the power to mix the liquid alone.

9–15 Characteristic of most applications of solids

. What are the disadvantages of vortex formation in

suspension and dissolution; a velocity of

mixing operations? 9 cm/s will suspend all solids with the

& Once vortex reaches impeller, severe air entrainment design settling velocity completely off

may occur. the bottom of the vessel; provide slurry

uniformity to at least one-third of the

& In addition to air entrainment, swirling mass of liquid

liquid level; be suitable for slurry draw-

may generate an oscillating surge in the tank, which,

off at low exit nozzle locations

coupled with the deep vortex, may create a large Gas dispersions

fluctuating force acting on the shaft. 3–6 Usedwhendegree of dispersion is not critical

. What are the undesirable effects of vortex shedding? to the process; a velocity of 6 cm/s will

& Severe vibration. provide nonflooded impeller conditions

for coarse dispersion; be typical of situa-

& Mechanical failure of cylindrical elements such as

tions that are not mass transfer limited

suspended piping, transmission lines, heat exchanger 9–15 Used where moderate degree of dispersion

tubes, columns, stacks, and so on. is needed; a velocity of 15 m/s will drive

. How are vortices broken/eliminated? fine bubbles completely to the wall of the

& By the use of baffled tanks and vortex breakers. For vessel; provide recirculation of dispersed

bubbles back into the impeller

axial flow impellers, the effect of full baffling can be

18–30 Used where rapid mass transfer is needed; a

achieved in an unbaffled vessel with an off-center and

velocity of 30 cm/s will maximize inter-

angled impeller shaft location. Off-center angled

facial area and recirculation of dispersed

shaft eliminates vortexing and swirling to a large bubbles through the impeller

extent.