Page 193 - Fluid mechanics, heat transfer, and mass transfer

P. 193

MIXING EQUIPMENT 171

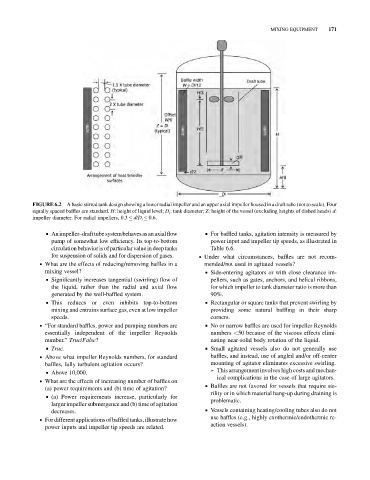

FIGURE 6.2 A basic stirred tank design showing a lower radial impeller and an upper axial impeller housed in a draft tube (not to scale). Four

equally spaced baffles are standard. H: height of liquid level; D i : tank diameter; Z: height of the vessel (excluding heights of dished heads) d:

impeller diameter. For radial impellers, 0.3 d/D i 0.6.

& Animpeller–drafttubesystembehavesasanaxialflow & For baffled tanks, agitation intensity is measured by

pump of somewhat low efficiency. Its top-to-bottom power input and impeller tip speeds, as illustrated in

circulationbehaviorisofparticularvalueindeeptanks Table 6.6.

for suspension of solids and for dispersion of gases. . Under what circumstances, baffles are not recom-

. What are the effects of reducing/removing baffles in a mended/not used in agitated vessels?

mixing vessel? & Side-entering agitators or with close clearance im-

& Significantly increases tangential (swirling) flow of pellers, such as gates, anchors, and helical ribbons,

the liquid, rather than the radial and axial flow for which impeller to tank diameter ratio is more than

generated by the well-baffled system. 90%.

& This reduces or even inhibits top-to-bottom & Rectangular or square tanks that prevent swirling by

mixing and entrains surface gas, even at low impeller providing some natural baffling in their sharp

speeds. corners.

. “For standard baffles, power and pumping numbers are & No or narrow baffles are used for impeller Reynolds

essentially independent of the impeller Reynolds numbers <50 because of the viscous effects elimi-

number.” True/False? nating near-solid body rotation of the liquid.

& True. & Small agitated vessels also do not generally use

. Above what impeller Reynolds numbers, for standard baffles, and instead, use of angled and/or off-center

baffles, fully turbulent agitation occurs? mounting of agitator eliminates excessive swirling.

➢ This arrangement involves high costs and mechan-

& Above 10,000.

ical complications in the case of large agitators.

. What are the effects of increasing number of baffles on

& Baffles are not favored for vessels that require ste-

(a) power requirements and (b) time of agitation?

rility or in which material hang-up during draining is

& (a) Power requirements increase, particularly for

problematic.

larger impeller submergence and (b) time of agitation

decreases. & Vessels containing heating/cooling tubes also do not

use baffles (e.g., highly exothermic/endothermic re-

. For different applications of baffled tanks,illustrate how

action vessels).

power inputs and impeller tip speeds are related.