Page 197 - Fluid mechanics, heat transfer, and mass transfer

P. 197

MIXING EQUIPMENT 175

& A narrow blade turbine is used for liquid–liquid and

solid–liquid dispersions.

. What are the recommended dimension proportions used

in turbine agitated vessels?

& Tank to impeller diameter ratio ¼ 2–4.

& Impeller diameter ¼ 5m.

& Impeller blade width ¼ D/15.

& Maximum tank diameter ¼ 20 m.

Flat plate impeller with sawtooth edges.

FIGURE 6.6 & Liquid level ¼ one tank diameter, D.

& Impeller level above tank bottom ¼ one-third of the

& Flat plate impellers with sawtooth edges are suited to

tank diameter.

emulsification and dispersion. Since the shearing

& Four vertical baffles with baffle width ¼ D/10.

action is localized, baffles are not required. Figure 6.6

illustrates the design. . Name the types of impellers used for mixing low-

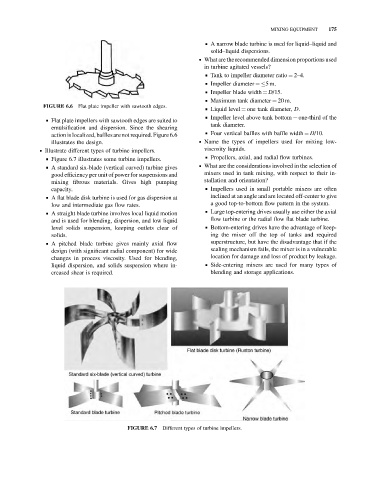

. Illustrate different types of turbine impellers. viscosity liquids.

& Propellers, axial, and radial flow turbines.

& Figure 6.7 illustrates some turbine impellers.

& A standard six-blade (vertical curved) turbine gives . What are the considerations involved in the selection of

good efficiency per unit of power for suspensions and mixers used in tank mixing, with respect to their in-

mixing fibrous materials. Gives high pumping stallation and orientation?

capacity. & Impellers used in small portable mixers are often

& A flat blade disk turbine is used for gas dispersion at inclined at an angle and are located off-center to give

low and intermediate gas flow rates. a good top-to-bottom flow pattern in the system.

& A straight blade turbine involves local liquid motion & Large top-entering drives usually use either the axial

and is used for blending, dispersion, and low liquid flow turbine or the radial flow flat blade turbine.

level solids suspension, keeping outlets clear of & Bottom-entering drives have the advantage of keep-

solids. ing the mixer off the top of tanks and required

& A pitched blade turbine gives mainly axial flow superstructure, but have the disadvantage that if the

design (with significant radial component) for wide sealing mechanism fails, the mixer is in a vulnerable

changes in process viscosity. Used for blending, location for damage and loss of product by leakage.

liquid dispersion, and solids suspension where in- & Side-entering mixers are used for many types of

creased shear is required. blending and storage applications.

FIGURE 6.7 Different types of turbine impellers.