Page 199 - Fluid mechanics, heat transfer, and mass transfer

P. 199

MIXING EQUIPMENT 177

TABLE 6.7 Advantages and Disadvantages of Selected Liquid Mixers

Type of Mixer Advantages Disadvantages

Paddle mixer Good radial and rotational flow; cheap Poor perpendicular flow; high vortex formation risk at higher speeds

Multiple paddle mixer Good flow in all three directions More expensive; higher energy requirements

Propeller mixer Good flow in all three directions More expensive than the paddle mixer

Turbine mixer Very good mixing Expensive; blockage risks

& The upflow in the annulus around the tube has

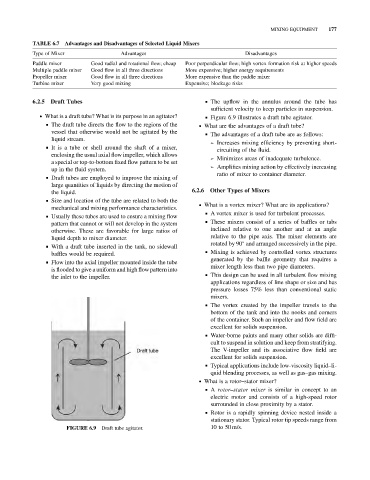

6.2.5 Draft Tubes

sufficient velocity to keep particles in suspension.

. What is a draft tube? What is its purpose in an agitator? & Figure 6.9 illustrates a draft tube agitator.

& The draft tube directs the flow to the regions of the . What are the advantages of a draft tube?

vessel that otherwise would not be agitated by the & The advantages of a draft tube are as follows:

liquid stream.

➢ Increases mixing efficiency by preventing short-

& It is a tube or shell around the shaft of a mixer,

circuiting of the fluid.

enclosing the usual axial flow impeller, which allows

➢ Minimizes areas of inadequate turbulence.

a special or top-to-bottom fixed flow pattern to be set

➢ Amplifies mixing action by effectively increasing

up in the fluid system.

ratio of mixer to container diameter.

& Draft tubes are employed to improve the mixing of

large quantities of liquids by directing the motion of

the liquid. 6.2.6 Other Types of Mixers

& Size and location of the tube are related to both the

. What is a vortex mixer? What are its applications?

mechanical and mixing performance characteristics.

& A vortex mixer is used for turbulent processes.

& Usually these tubes are used to ensure a mixing flow

& These mixers consist of a series of baffles or tabs

pattern that cannot or will not develop in the system

otherwise. These are favorable for large ratios of inclined relative to one another and at an angle

liquid depth to mixer diameter. relative to the pipe axis. The mixer elements are

rotated by 90 and arranged successively in the pipe.

& With a draft tube inserted in the tank, no sidewall

& Mixing is achieved by controlled vortex structures

baffles would be required.

generated by the baffle geometry that requires a

& Flow into the axial impeller mounted inside the tube

mixer length less than two pipe diameters.

is flooded to give a uniform and high flow pattern into

& This design can be used in all turbulent flow mixing

the inlet to the impeller.

applications regardless of line shape or size and has

pressure losses 75% less than conventional static

mixers.

& The vortex created by the impeller travels to the

bottom of the tank and into the nooks and corners

of the container. Such an impeller and flow field are

excellent for solids suspension.

& Water-borne paints and many other solids are diffi-

cult to suspend in solution and keep from stratifying.

The V-impeller and its associative flow field are

excellent for solids suspension.

& Typical applications include low-viscosity liquid–li-

quid blending processes, as well as gas–gas mixing.

. What is a rotor–stator mixer?

& A rotor–stator mixer is similar in concept to an

electric motor and consists of a high-speed rotor

surrounded in close proximity by a stator.

& Rotor is a rapidly spinning device nested inside a

stationary stator. Typical rotor tip speeds range from

Draft tube agitator. 10 to 50 m/s.

FIGURE 6.9