Page 202 - Fluid mechanics, heat transfer, and mass transfer

P. 202

MIXING

180

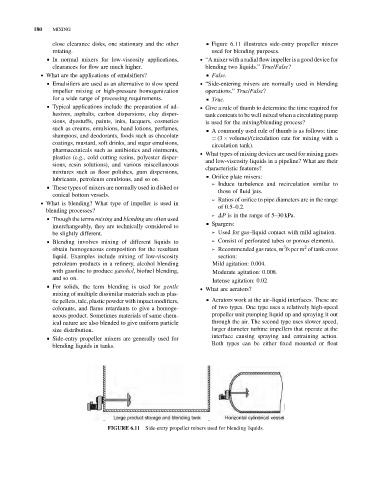

close clearance disks, one stationary and the other & Figure 6.11 illustrates side-entry propeller mixers

rotating. used for blending purposes.

& In normal mixers for low-viscosity applications, . “A mixer with a radial flow impeller is a good device for

clearances for flow are much higher. blending two liquids.” True/False?

. What are the applications of emulsifiers? & False.

& Emulsifiers are used as an alternative to slow speed . “Side-entering mixers are normally used in blending

impeller mixing or high-pressure homogenization operations.” True/False?

for a wide range of processing requirements. & True.

& Typical applications include the preparation of ad- . Give a rule of thumb to determine the time required for

hesives, asphalts, carbon dispersions, clay disper- tank contents to be well mixed when a circulating pump

sions, dyestuffs, paints, inks, lacquers, cosmetics is used for the mixing/blending process?

such as creams, emulsions, hand lotions, perfumes, & A commonly used rule of thumb is as follows: time

shampoos, and deodorants, foods such as chocolate

¼ (3 volume)/(circulation rate for mixing with a

coatings, mustard, soft drinks, and sugar emulsions,

circulation tank).

pharmaceuticals such as antibiotics and ointments,

. What types of mixing devices are used for mixing gases

plastics (e.g., cold cutting resins, polyester disper-

and low-viscosity liquids in a pipeline? What are their

sions, resin solutions), and various miscellaneous

characteristic features?

mixtures such as floor polishes, gum dispersions,

& Orifice plate mixers:

lubricants, petroleum emulsions, and so on.

➢ Induce turbulence and recirculation similar to

& These types of mixers are normally used in dished or

those of fluid jets.

conical bottom vessels.

➢ Ratios of orifice to pipe diameters are in the range

. What is blending? What type of impeller is used in

of 0.5–0.2.

blending processes?

➢ DP is in the range of 5–30 kPa.

& Though the terms mixing and blending are often used

& Spargers:

interchangeably, they are technically considered to

be slightly different. ➢ Used for gas–liquid contact with mild agitation.

& Blending involves mixing of different liquids to ➢ Consist of perforated tubes or porous elements.

3

2

obtain homogeneous composition for the resultant ➢ Recommended gas rates, m /s per m of tank cross

liquid. Examples include mixing of low-viscosity section:

petroleum products in a refinery, alcohol blending Mild agitation: 0.004.

with gasoline to produce gasohol, biofuel blending, Moderate agitation: 0.008.

and so on.

Intense agitation: 0.02

& For solids, the term blending is used for gentle

. What are aerators?

mixing of multiple dissimilar materials such as plas-

tic pellets, talc, plastic powder with impact modifiers, & Aerators work at the air–liquid interfaces. These are

colorants, and flame retardants to give a homoge- of two types. One type uses a relatively high-speed

neous product. Sometimes materials of same chem- propeller unit pumping liquid up and spraying it out

ical nature are also blended to give uniform particle through the air. The second type uses slower speed,

size distribution. larger diameter turbine impellers that operate at the

interface causing spraying and entraining action.

& Side-entry propeller mixers are generally used for

Both types can be either fixed mounted or float

blending liquids in tanks.

Side-entry propeller mixers used for blending liquids.

FIGURE 6.11