Page 205 - Fluid mechanics, heat transfer, and mass transfer

P. 205

MIXING EQUIPMENT 183

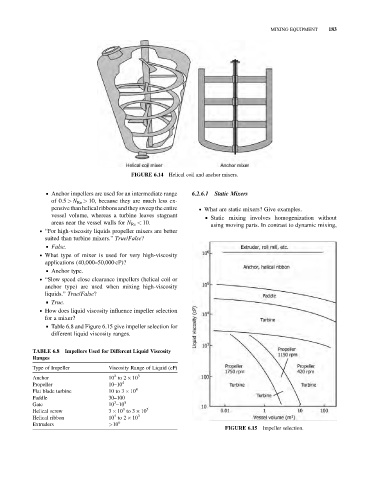

Helical coil and anchor mixers.

FIGURE 6.14

& Anchor impellers are used for an intermediate range 6.2.6.1 Static Mixers

of 0.5 > N Re > 10, because they are much less ex-

pensivethan helical ribbons and they sweep the entire . What are static mixers? Give examples.

vessel volume, whereas a turbine leaves stagnant

& Static mixing involves homogenization without

areas near the vessel walls for N Re < 10.

using moving parts. In contrast to dynamic mixing,

. “For high-viscosity liquids propeller mixers are better

suited than turbine mixers.” True/False?

& False.

. What type of mixer is used for very high-viscosity

applications (40,000–50,000 cP)?

& Anchor type.

. “Slow speed close clearance impellers (helical coil or

anchor type) are used when mixing high-viscosity

liquids.” True/False?

& True.

. How does liquid viscosity influence impeller selection

for a mixer?

& Table 6.8 and Figure 6.15 give impeller selection for

different liquid viscosity ranges.

TABLE 6.8 Impellers Used for Different Liquid Viscosity

Ranges

Type of Impeller Viscosity Range of Liquid (cP)

2

Anchor 10 to 2 10 3

Propeller 10–10 4

Flat blade turbine 10 to 3 10 4

Paddle 30–100

3

Gate 10 –10 5

3

Helical screw 3 10 to 3 10 5

4

Helical ribbon 10 to 2 10 3

Extruders >10 6

FIGURE 6.15 Impeller selection.