Page 206 - Fluid mechanics, heat transfer, and mass transfer

P. 206

MIXING

184

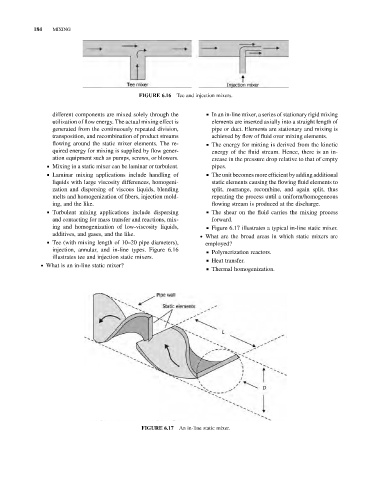

Tee and injection mixers.

FIGURE 6.16

different components are mixed solely through the & In an in-line mixer, a series of stationary rigid mixing

utilization of flow energy. The actual mixing effect is elements are inserted axially into a straight length of

generated from the continuously repeated division, pipe or duct. Elements are stationary and mixing is

transposition, and recombination of product streams achieved by flow of fluid over mixing elements.

flowing around the static mixer elements. The re- & The energy for mixing is derived from the kinetic

quired energy for mixing is supplied by flow gener- energy of the fluid stream. Hence, there is an in-

ation equipment such as pumps, screws, or blowers. crease in the pressure drop relative to that of empty

& Mixing in a static mixer can be laminar or turbulent. pipes.

& Laminar mixing applications include handling of & The unit becomes more efficient by adding additional

liquids with large viscosity differences, homogeni- static elements causing the flowing fluid elements to

zation and dispersing of viscous liquids, blending split, rearrange, recombine, and again split, thus

melts and homogenization of fibers, injection mold- repeating the process until a uniform/homogeneous

ing, and the like. flowing stream is produced at the discharge.

& Turbulent mixing applications include dispersing & The shear on the fluid carries the mixing process

and contacting for mass transfer and reactions, mix- forward.

ing and homogenization of low-viscosity liquids, & Figure 6.17 illustrates a typical in-line static mixer.

additives, and gases, and the like. . What are the broad areas in which static mixers are

& Tee (with mixing length of 10–20 pipe diameters),

employed?

injection, annular, and in-line types. Figure 6.16 & Polymerization reactors.

illustrates tee and injection static mixers.

& Heat transfer.

. What is an in-line static mixer?

& Thermal homogenization.

An in-line static mixer.

FIGURE 6.17