Page 194 - Fluid mechanics, heat transfer, and mass transfer

P. 194

MIXING

172

TABLE 6.6 Power Input and Impeller Tip Speeds for Baffled Tanks

Power Requirements Tip Speeds

3

Process (kW/m ) (hp/1000 gal) (m/s) (ft/s)

Blending 0.033–0.082 0.2–0.5 – –

Homogeneous reaction 0.082–0.247 0.5–1.5 2.29–3.05 7.5–10

Reaction with heat transfer 0.247–0.824 1.5–5.0 3.05–4.57 10–15

Liquid–liquid mixtures 0.824 5.0 4.57–6.09 15–20

Liquid–gas mixtures 0.824–1.647 5–10 4.57–6.09 15–20

Slurries 1.647 10 – –

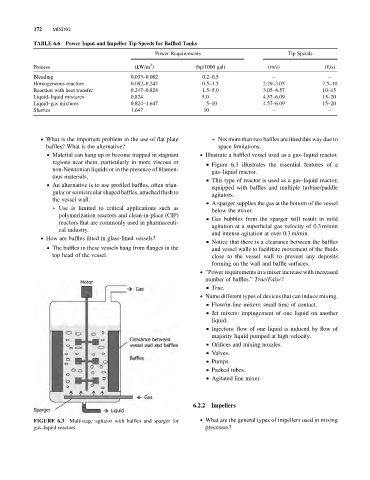

. What is the important problem in the use of flat plate ➢ Not more than two baffles are fitted this way due to

baffles? What is the alternative? space limitations.

& Material can hang up or become trapped in stagnant . Illustrate a baffled vessel used as a gas–liquid reactor.

regions near them, particularly in more viscous or & Figure 6.3 illustrates the essential features of a

non-Newtonian liquids or in the presence of filamen-

gas–liquid reactor.

tous materials.

& This type of reactor is used as a gas–liquid reactor,

& An alternative is to use profiled baffles, often trian-

equipped with baffles and multiple turbine/paddle

gular or semicircular shaped baffles, attached flush to

agitators.

the vessel wall.

& A sparger supplies the gas at the bottom of the vessel

➢ Use is limited to critical applications such as

below the mixer.

polymerization reactors and clean-in-place (CIP)

& Gas bubbles from the sparger will result in mild

reactors that are commonly used in pharmaceuti-

agitation at a superficial gas velocity of 0.3 m/min

cal industry.

and intense agitation at over 0.3 m/min.

. How are baffles fitted in glass-lined vessels?

& Notice that there is a clearance between the baffles

& The baffles in these vessels hang from flanges in the

and vessel walls to facilitate movement of the fluids

top head of the vessel. close to the vessel wall to prevent any deposits

forming on the wall and baffle surfaces.

. “Power requirements in a mixer increase with increased

number of baffles.” True/False?

& True.

. Name different types of devices that can induce mixing.

& Flow/in-line mixers: small time of contact.

& Jet mixers: impingement of one liquid on another

liquid.

& Injectors: flow of one liquid is induced by flow of

majority liquid pumped at high velocity.

& Orifices and mixing nozzles.

& Valves.

& Pumps.

& Packed tubes.

& Agitated line mixer.

6.2.2 Impellers

Multistage agitator with baffles and sparger for . What are the general types of impellers used in mixing

FIGURE 6.3

gas–liquid reactors. processes?