Page 86 - Fluid mechanics, heat transfer, and mass transfer

P. 86

FLOW MEASUREMENT 63

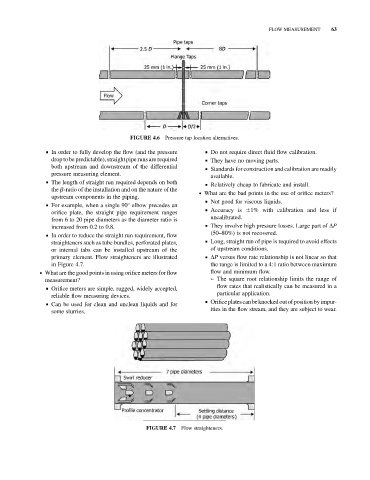

Pressure tap location alternatives.

FIGURE 4.6

& In order to fully develop the flow (and the pressure & Do not require direct fluid flow calibration.

drop to be predictable), straight pipe runs are required & They have no moving parts.

both upstream and downstream of the differential & Standards for construction and calibration are readily

pressure measuring element.

available.

& The length of straight run required depends on both

& Relatively cheap to fabricate and install.

the b-ratio of the installation and on the nature of the

. What are the bad points in the use of orifice meters?

upstream components in the piping.

& Not good for viscous liquids.

& For example, when a single 90 elbow precedes an

& Accuracy is 1% with calibration and less if

orifice plate, the straight pipe requirement ranges

uncalibrated.

from 6 to 20 pipe diameters as the diameter ratio is

increased from 0.2 to 0.8. & They involve high pressure losses. Large part of DP

(50–80%) is not recovered.

& In order to reduce the straight run requirement, flow

straighteners such as tube bundles, perforated plates, & Long, straight run of pipe is required to avoid effects

or internal tabs can be installed upstream of the of upstream conditions.

primary element. Flow straighteners are illustrated & DP versus flow rate relationship is not linear so that

in Figure 4.7. the range is limited to a 4:1 ratio between maximum

. What are the good points in using orifice meters for flow flow and minimum flow.

measurement? ➢ The square root relationship limits the range of

flow rates that realistically can be measured in a

& Orifice meters are simple, rugged, widely accepted,

particular application.

reliable flow measuring devices.

& Orificeplatescanbeknockedoutofpositionbyimpur-

& Can be used for clean and unclean liquids and for

ities in the flow stream, and they are subject to wear.

some slurries.

FIGURE 4.7 Flow straighteners.