Page 91 - Fluid mechanics, heat transfer, and mass transfer

P. 91

FLOW MEASUREMENT

68

& Lower pressure indication than real flow pressure if & The downstream end of a nozzle is a short tube having

tap is located in an area of high velocity. the same diameter as the vena contracta of an equiv-

& Presence of swirling flow or abnormal velocity dis- alent orifice plate.

tribution upstream can cause serious errors in & The low b-ratio designs range in diameter ratios from

measurements. 0.2 to 0.5, while the high b-ratio designs vary be-

& Flow pulsations can give rise to undependable tween 0.45 and 0.8.

measurements. & The nozzle should always be centered in the pipe and

& Presence of gas bubbles in liquid flow or entrained the downstream pressure tap should be inside the

liquid in gas flow in piping and/or gas bubbles in nozzle exit.

manometer leads cause errors in measurements. & The throat taper should always decrease the diameter

& Use of purge gas to keep the tap from plugging can toward the exit.

cause a high pressure reading if too much of purgegas & The most common flow nozzle is the flange type.

is used. Taps are commonly located 1 pipe diameter upstream

& If tap is located below a liquid level, reading will be and 0.5 pipe diameter downstream from the inlet

too high. face.

& For gases, due to the low DP values (low head & A major disadvantage of the nozzle is that it is more

differentials), measuring accuracy is poor. At low difficult to replace than the orifice.

velocities, differentials are extremely low. . What are the characteristics and applications of flow

nozzles?

& Flow nozzle has characteristics similar to those of the

venturi meter, but is shorter and much less expensive.

4.1.2 Other Differential Pressure Flow Meters

& It is recommended generally for clean liquids and

. What is a flow nozzle? Give a diagram and describe its

gases. Applicable to some slurry systems, but nor-

features.

mally not recommendedfor slurries or unclean fluids.

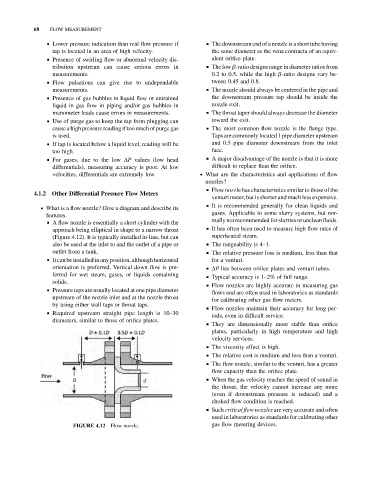

& A flow nozzle is essentially a short cylinder with the

approach being elliptical in shape to a narrow throat & It has often been used to measure high flow rates of

(Figure 4.12). It is typically installed in-line, but can superheated steam.

also be used at the inlet to and the outlet of a pipe or & The rangeability is 4–1.

outlet from a tank. & The relative pressure loss is medium, less than that

& It can be installed in anyposition, although horizontal for a venturi.

orientation is preferred. Vertical down flow is pre- & DP lies between orifice plates and venturi tubes.

ferred for wet steam, gases, or liquids containing & Typical accuracy is 1–2% of full range.

solids.

& Flow nozzles are highly accurate in measuring gas

& Pressure taps are usually located at one pipe diameter

flows and are often used in laboratories as standards

upstream of the nozzle inlet and at the nozzle throat

for calibrating other gas flow meters.

by using either wall taps or throat taps.

& Flow nozzles maintain their accuracy for long per-

& Required upstream straight pipe length is 10–30

iods, even in difficult service.

diameters, similar to those of orifice plates.

& They are dimensionally more stable than orifice

plates, particularly in high temperature and high

velocity services.

& The viscosity effect is high.

& The relative cost is medium and less than a venturi.

& The flow nozzle, similar to the venturi, has a greater

flow capacity than the orifice plate.

& When the gas velocity reaches the speed of sound in

the throat, the velocity cannot increase any more

(even if downstream pressure is reduced) and a

choked flow condition is reached.

& Such critical flow nozzles are very accurate and often

used in laboratories as standards for calibrating other

FIGURE 4.12 Flow nozzle. gas flow metering devices.