Page 123 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 123

Compressor Best Practices Be st Practice 3.1

the rotor threads pass the edges of the inlet ports and trap

the gas in the cell that is formed by the rotor cavities and the

cylinder wall. Further rotation causes the male rotor thread

to roll into the female rotor groove and to decrease the

volume of the cell. The decrease in the volume increases the

cell pressure. Oil is normally injected after the cell is closed

to the inlet port. The oil seals the clearances between the

threads and the grooves, and it absorbs the heat of com-

pression. Compression continues until the rotor threads pass

theedgeofthe dischargeport and releasethe compressedgas

and oil mixture. A typical single stage screw compressor is

shown in Figure 3.1.4.

Rotary liquid ring

Liquid ring rotary compressors consist of a round, multi-

blade rotor that revolves in an elliptical casing. The elliptical

Fig 3.1.3 Rotary vane

casing is partially filled with a liquid, which is usually water.

As the rotor turns, the blades form a series of buckets which

carry the liquid around with the rotor. Because the liquid

proportional to the thread-groove ratio. In the four-thread, six- follows the contour of the casing, it alternately leaves and

groove, screw compressor, when the male rotor rotates at 1800 returns to the space between the blades. The space between

rpm, the female rotor rotates at 1200 rpm. thebladesservesas a rotorchamber.The gasinlet anddis-

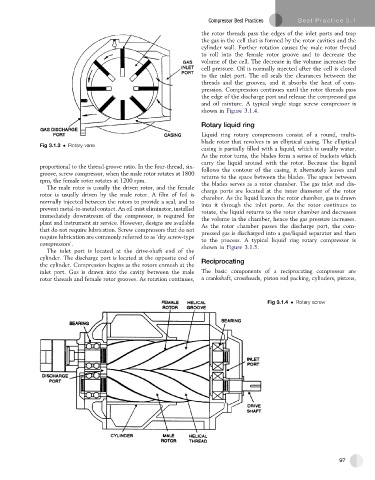

The male rotor is usually the driven rotor, and the female charge ports are located at the inner diameter of the rotor

rotor is usually driven by the male rotor. A film of foil is chamber. As the liquid leaves the rotor chamber, gas is drawn

normally injected between the rotors to provide a seal, and to into it through the inlet ports. As the rotor continues to

prevent metal-to-metal contact. An oil-mist eliminator, installed rotate, the liquid returns to the rotor chamber and decreases

immediately downstream of the compressor, is required for thevolumeinthe chamber,hencethegaspressureincreases.

plant and instrument air service. However, designs are available As the rotor chamber passes the discharge port, the com-

that do not require lubrication. Screw compressors that do not pressed gas is discharged into a gas/liquid separator and then

require lubrication are commonly referred to as ‘dry screw-type to the process. A typical liquid ring rotary compressor is

compressors’. shown in Figure 3.1.5.

The inlet port is located at the drive-shaft end of the

cylinder. The discharge port is located at the opposite end of Reciprocating

the cylinder. Compression begins as the rotors enmesh at the

inlet port. Gas is drawn into the cavity between the male The basic components of a reciprocating compressor are

rotor threads and female rotor grooves. As rotation continues, a crankshaft, crossheads, piston rod packing, cylinders, pistons,

Fig 3.1.4 Rotary screw

97