Page 122 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 122

Be st Practice 3 .1 Compressor Best Practices

Table 3.1.2 Typical compressor applications

Compressor Type Application

Rotary lobe Conveying e powder, polyethylene

Rotary vane air Air blowers (low volume). Also used as gas turbine starters

Rotary screw Plant and instrument air, low flow process e off gas, recycle, sulfur blowers

Rotary liquid ring Crude unit vacuum, various saturated gas applications

Reciprocating Plant and instrument air off gas (low flow) recycle (low flow) H 2 make-up, gas reinjection (low flow)

Centrifugal single stage Air blowers, recycle

Centrifugal single stage e integral gear Low flow recycle, off gas, plant air (can replace a recip. in low flow, medium to high molecular weight

applications)

Centrifugal multi-stage side load (horizontal split (Propane, propylene, ethylene, Freon, mixed gas) refrigeration

or barrel)

Centrifugal multi-stage barrel Recycle, reinjection, syn gas

Centrifugal multi-stage e integral gear Plant and instrument air *Process applications require proven field experience

Axial compressor FCC blower, MTBE effluent, gas turbine air

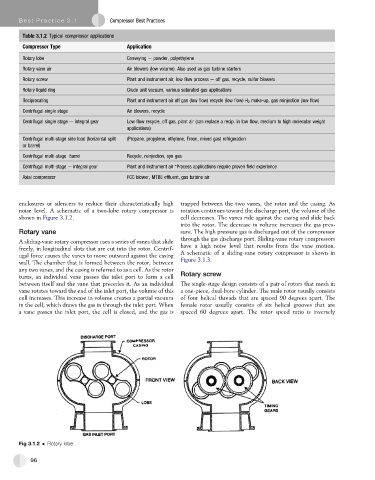

enclosures or silencers to reduce their characteristically high trapped between the two vanes, the rotor and the casing. As

noise level. A schematic of a two-lobe rotary compressor is rotation continues toward the discharge port, the volume of the

shown in Figure 3.1.2. cell decreases. The vanes ride against the casing and slide back

into the rotor. The decrease in volume increases the gas pres-

Rotary vane sure. The high pressure gas is discharged out of the compressor

through the gas discharge port. Sliding-vane rotary compressors

A sliding-vane rotary compressor uses a series of vanes that slide

freely, in longitudinal slots that are cut into the rotor. Centrif- have a high noise level that results from the vane motion.

ugal force causes the vanes to move outward against the casing A schematic of a sliding-vane rotary compressor is shown in

wall. The chamber that is formed between the rotor, between Figure 3.1.3.

any two vanes, and the casing is referred to as a cell. As the rotor

turns, an individual vane passes the inlet port to form a cell Rotary screw

between itself and the vane that precedes it. As an individual The single-stage design consists of a pair of rotors that mesh in

vane rotates toward the end of the inlet port, the volume of this a one-piece, dual-bore cylinder. The male rotor usually consists

cell increases. This increase in volume creates a partial vacuum of four helical threads that are spaced 90 degrees apart. The

in the cell, which draws the gas in through the inlet port. When female rotor usually consists of six helical grooves that are

a vane passes the inlet port, the cell is closed, and the gas is spaced 60 degrees apart. The rotor speed ratio is inversely

Fig 3.1.2 Rotary lobe

96