Page 117 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 117

Be st Practice 2 .24 Pump Best Practices

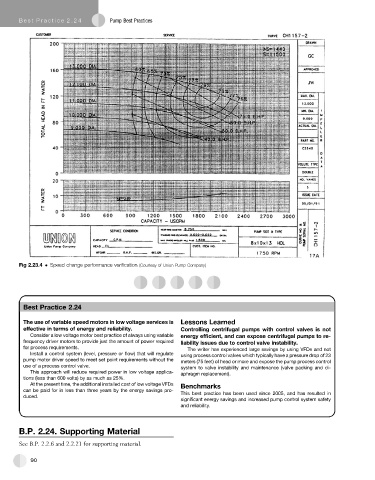

Fig 2.23.4 Speed change performance verification (Courtesy of Union Pump Company)

Best Practice 2.24

The use of variable speed motors in low voltage services is Lessons Learned

effective in terms of energy and reliability. Controlling centrifugal pumps with control valves is not

Consider a low voltage motor best practice of always using variable energy efficient, and can expose centrifugal pumps to re-

frequency driver motors to provide just the amount of power required liability issues due to control valve instability.

for process requirements. The writer has experienced large savings by using VFDs and not

Install a control system (level, pressure or flow) that will regulate using process control valves which typically have a pressure drop of 23

pump motor driver speed to meet set point requirements without the meters (75 feet) of head or more and expose the pump process control

use of a process control valve. system to valve instability and maintenance (valve packing and di-

This approach will reduce required power in low voltage applica- aphragm replacement).

tions (less than 600 volts) by as much as 25%.

At the present time, the additional installed cost of low voltage VFDs Benchmarks

can be paid for in less than three years by the energy savings pro- This best practice has been used since 2005, and has resulted in

duced.

significant energy savings and increased pump control system safety

and reliability.

B.P. 2.24. Supporting Material

See B.P. 2.2.6 and 2.2.21 for supporting material.

90