Page 114 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 114

Pump Best Practices Best Practice 2 .22

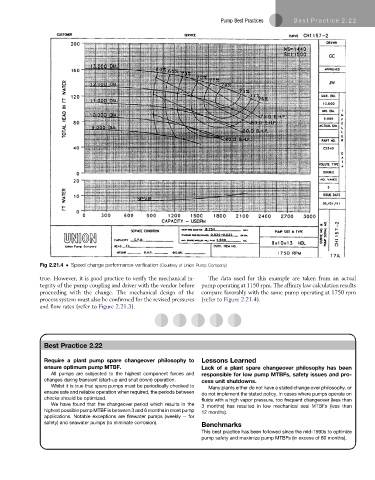

Fig 2.21.4 Speed change performance verification (Courtesy of Union Pump Company)

true. However, it is good practice to verify the mechanical in- The data used for this example are taken from an actual

tegrity of the pump coupling and driver with the vendor before pump operating at 1150 rpm. The affinity law calculation results

proceeding with the change. The mechanical design of the compare favorably with the same pump operating at 1750 rpm

process system must also be confirmed for the revised pressures (refer to Figure 2.21.4).

and flow rates (refer to Figure 2.21.3).

Best Practice 2.22

Require a plant pump spare changeover philosophy to Lessons Learned

ensure optimum pump MTBF. Lack of a plant spare changeover philosophy has been

All pumps are subjected to the highest component forces and responsible for low pump MTBFs, safety issues and pro-

changes during transient (start-up and shut down) operation. cess unit shutdowns.

Whilst it is true that spare pumps must be periodically checked to Many plants either do not have a stated change over philosophy, or

ensure safe and reliable operation when required, the periods between

do not implement the stated policy. In cases where pumps operate on

checks should be optimized.

fluids with a high vapor pressure, too frequent changeover (less than

We have found that the changeover period which results in the

3 months) has resulted in low mechanical seal MTBFs (less than

highest possible pump MTBF is between 3 and 6 months in most pump

12 months).

applications. Notable exceptions are firewater pumps (weekly e for

safety) and seawater pumps (to eliminate corrosion).

Benchmarks

This best practice has been followed since the mid-1990s to optimize

pump safety and maximize pump MTBFs (in excess of 80 months).