Page 127 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 127

Compressor Best Practices Be st Practice 3.1

piped to the second stage. The discharge from the second

stage enters an intercooler, and then it is piped to the third

stage.

Axial horizontal split

A typical axial compressor is shown in Figure 3.1.15.Anaxial

compressor consists of a rotor shaft with a series of rotating

blades, and a tapered cylindrical casing with fixed stator vanes.

Each set of blades is followed by a set of stator vanes. The gas

enters the inlet nozzle, which guides it to the inlet volute. The

inletvoluteguidesand acceleratesthe gasstream intothe

stator vanes. The stator vanes turn the gas stream to properly

align the gas with the blades. The blades increase the energy

of the gas by increasing its velocity. The stator vanes act as

diffusers to provide resistance to the gas flow, and they cause

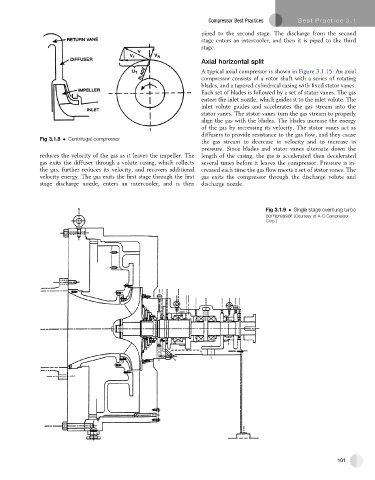

Fig 3.1.8 Centrifugal compressor

the gas stream to decrease in velocity and to increase in

pressure. Since blades and stator vanes alternate down the

reduces the velocity of the gas as it leaves the impeller. The length of the casing, the gas is accelerated then decelerated

gas exits the diffuser through a volute casing, which collects several times before it leaves the compressor. Pressure is in-

the gas, further reduces its velocity, and recovers additional creased each time the gas flow meets a set of stator vanes. The

velocity energy. The gas exits the first stage through the first gas exits the compressor through the discharge volute and

stage discharge nozzle, enters an intercooler, and is then discharge nozzle.

Fig 3.1.9 Single stage overhung turbo

compressor (Courtesy of A-C Compressor

Corp.)

101