Page 132 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 132

Be st Practice 3 .2 Compressor Best Practices

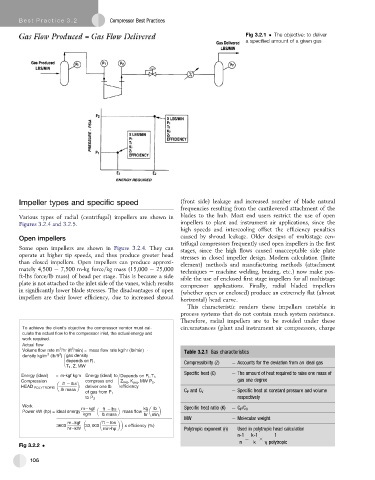

Fig 3.2.1 The objective: to deliver

a specified amount of a given gas

Impeller types and specific speed (front side) leakage and increased number of blade natural

frequencies resulting from the cantilevered attachment of the

Various types of radial (centrifugal) impellers are shown in blades to the hub. Most end users restrict the use of open

Figures 3.2.4 and 3.2.5. impellers to plant and instrument air applications, since the

high speeds and intercooling offset the efficiency penalties

Open impellers caused by shroud leakage. Older designs of multistage cen-

trifugal compressors frequently used open impellers in the first

Some open impellers are shown in Figure 3.2.4. They can

stages, since the high flows caused unacceptable side plate

operate at higher tip speeds, and thus produce greater head stresses in closed impeller design. Modern calculation (finite

than closed impellers. Open impellers can produce approxi- element) methods and manufacturing methods (attachment

mately 4,500 e 7,500 m-kg force/kg mass (15,000 e 25,000 techniques e machine welding, brazing, etc.) now make pos-

ft-lbs force/lb mass) of head per stage. This is because a side sible the use of enclosed first stage impellers for all multistage

plate is not attached to the inlet side of the vanes, which results compressor applications. Finally, radial bladed impellers

in significantly lower blade stresses. The disadvantages of open (whether open or enclosed) produce an extremely flat (almost

impellers are their lower efficiency, due to increased shroud horizontal) head curve.

This characteristic renders these impellers unstable in

process systems that do not contain much system resistance.

Therefore, radial impellers are to be avoided under these

To achieve the client's objective the compressor vendor must cal- circumstances (plant and instrument air compressors, charge

culate the actual flow to the compressor inlet, the actual energy and

work required.

Actual flow

Volume flow rate m /hr (ft /min) = mass flow rate kg/hr (lb/min) × Table 3.2.1 Gas characteristics

3

3

3

3

density kg/m (lb/ft ) gas density

depends on P 1 , Compressibility (Z) Accounts for the deviation from an ideal gas

T 1 ,Z, MW

Specific heat (C) The amount of heat required to raise one mass of

Energy (ideal) = m-kgf kgm Energy (ideal) to Depends on P 1 ,T 1 ,

Compression compress and Z avg ,K avg ,MW P 2 , gas one degree

ft lbs

HEAD POLYTROPIC deliver one lb efficiency

lb mass C P and C V Specific heat at constant pressure and volume

of gas from P 1

respectively

to P 2

Work Specific heat ratio (K)

m kgf ft – lbs kg lb C P /C V

–

Power kW (hp) = ideal energy mass flow

kgm lb mass hr min

MW Molecular weight

m kgf ft lbs

–

3600 33, 000 x efficiency (%)

hr kW min-hp Polytropic exponent (n) Used in polytropic head calculation

–

n-1 k-1 1

n ¼ k h polytropic

Fig 3.2.2

106