Page 290 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 290

Steam Turbine Best Practices Be st Practice 5.2

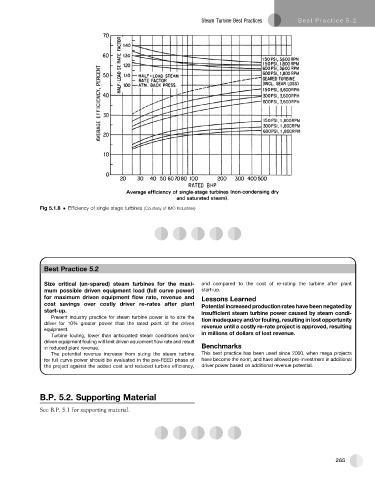

Fig 5.1.8 Efficiency of single stage turbines (Courtesy of IMO Industries)

Best Practice 5.2

Size critical (un-spared) steam turbines for the maxi- and compared to the cost of re-rating the turbine after plant

mum possible driven equipment load (full curve power) start-up.

for maximum driven equipment flow rate, revenue and Lessons Learned

cost savings over costly driver re-rates after plant

Potential increased production rates have been negated by

start-up.

insufficient steam turbine power caused by steam condi-

Present industry practice for steam turbine power is to size the tion inadequacy and/or fouling, resulting in lost opportunity

driver for 10% greater power than the rated point of the driven

equipment. revenue until a costly re-rate project is approved, resulting

in millions of dollars of lost revenue.

Turbine fouling, lower than anticipated steam conditions and/or

driven equipment fouling will limit driven equipment flow rate and result

in reduced plant revenue. Benchmarks

The potential revenue increase from sizing the steam turbine This best practice has been used since 2000, when mega projects

for full curve power should be evaluated in the pre-FEED phase of have become the norm, and have allowed pre-investment in additional

the project against the added cost and reduced turbine efficiency, driver power based on additional revenue potential.

B.P. 5.2. Supporting Material

See B.P. 5.1 for supporting material.

265