Page 292 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 292

Steam Turbine Best Practices Be st Practice 5.4

Best

Best Practice 5.4Practice 5.4Practice 5.4

Best

Trend “after first stage” pressures vs. steam flow, as well operations and reliability personnel with immediate indication of

as phase angle to detect the onset of steam path fouling, in fouling.

order to determine the necessity for water washing.

Ensure that after first stage, pressures are trended and plotted on Lessons Learned

vendor-provided “after first stage” pressure vs. steam flow curves. Failure to observe, trend and use the vendor’s “after first

If after the first stage, the pressure falls above the curve for stage” pressure vs. steam flow curve will result in un-

a measured steam flow, the turbine is beginning to foul. expected turbine vibration that can trip the unit on high

Further confirmation is any change in vibration phase angles once vibration.

abnormal first stage pressures are observed.

Fouling will initially accumulate evenly on a rotor, but will break off

Consult management, and plan for a timely on-line turbine water

unevenly, so causing unbalanced vibration that can reach levels that

wash, closely following vendor recommendations.

are high enough to trip the turbine.

The above procedure also applies to the post-first stage pressure in

the low pressure section of extraction turbines. Benchmarks

If transmitters are installed, this information can be brought into

the control room DCS and plotted on the vendor curves to provide This best practice has been used since the 1990s, achieving steam tur-

bine reliabilities above 99.5% and to direct timely on-line water washes.

B.P. 5.4. Supporting Material foulant cause it to chip off with time as it becomes dry and

brittle. This results in a change in rotor balance and a change in

performance (head and efficiency).

The mechanism of fouling

As mentioned earlier, one can reduce any blade row or impeller The effect of fouling on the operating point

to a series of equivalent orifices. Flow is a function of area and

velocity. If we refer back to the previous example of a backward leaning

Whenever any blade row or impeller is designed, the designer centrifugal compressor impeller, the effect of fouling can be

sets the inlet and discharge blade areas such that optimum ve- understood. Figure 5.4.2 shows the effect of fouling on the

locities relative to the blade will be achieved at each location. By relative velocity.

a combination of tests and experience, designers have defined Since the area of the flow passage is reduced when the im-

optimum relative velocity rather well. Therefore the resulting peller is fouled, V REL will increase, the flow angle, f, will in-

inlet and discharge areas will produce optimum velocities and crease, and therefore result in an absolute velocity (increased R)

corresponding optimum impeller efficiencies. If, however, the as shown in Figure 5.4.3.

areas were to change, and flow passages were to become rough The increase in f and R due to fouling will reduce the tan-

and non-continuous, the performance of the impeller would gential velocity of the gas as shown in Figure 5.4.4.

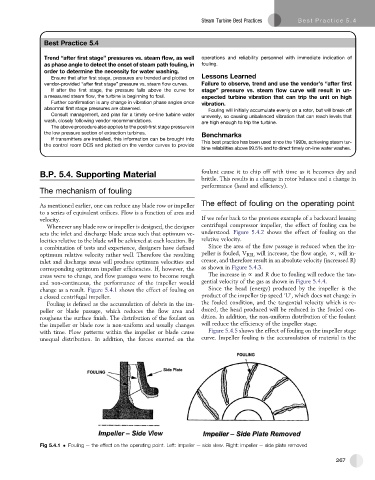

change as a result. Figure 5.4.1 shows the effect of fouling on Since the head (energy) produced by the impeller is the

a closed centrifugal impeller. product of the impeller tip speed ‘U’, which does not change in

Fouling is defined as the accumulation of debris in the im- the fouled condition, and the tangential velocity which is re-

peller or blade passage, which reduces the flow area and duced, the head produced will be reduced in the fouled con-

roughens the surface finish. The distribution of the foulant on dition. In addition, the non-uniform distribution of the foulant

the impeller or blade row is non-uniform and usually changes will reduce the efficiency of the impeller stage.

with time. Flow patterns within the impeller or blade cause Figure 5.4.5 shows the effect of fouling on the impeller stage

unequal distribution. In addition, the forces exerted on the curve. Impeller fouling is the accumulation of material in the

Fig 5.4.1 Fouling e the effect on the operating point. Left: impeller e side view. Right: impeller e side plate removed

267